Blood processing equipment including Cooling equipment,Blood Seperate Equipment,Plasma Concentration,Freezing and Drying Equipment. After animal blood collection step, you will have the approval fresh blood which can be used for furthermore processing which can be used for food industry, or make edible blood product.

Blood processing equipment

Cooling equipment

After collection, the blood should be cooling down to 4~10°C, it can be carried out by mean of ddiffernt types of heat exchanger, or cooling tank which similar to milk tank which used at farms. to desided which kind of heat exchanger, mostly depand on the volume and other circumstances. the most efficient cooler is duplex heat exchanger, Cooling in a tank will bring too long cooling time, also creating a slight hemolysis, when adding the warmer blood to the be cooled blood is also a issue.

Duplex heat exchanger euipemnt

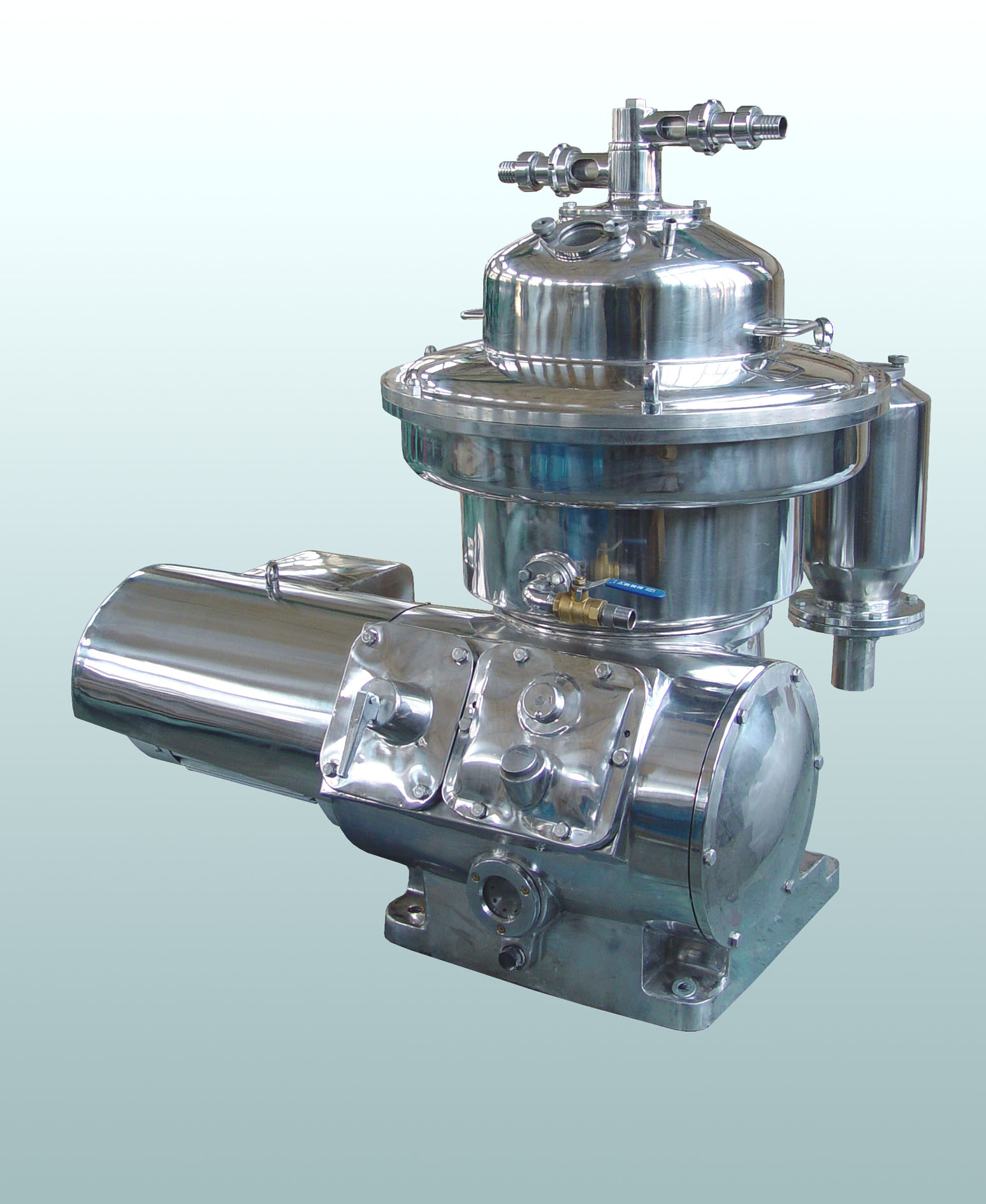

Animal Blood Seperate Equipment

Seperation can be taken both cooled blood and warm blood, however warm blood seperating capacity is higher than cooled blood. after seperation, you’ll get the plasma and hemoglobin, due of bacteria 60~80% are going with hemoglobin, then after seperation, the temperature must be cooling down to 3°C or even lower.

Blood seperator are using modified milk seperator

Blood seperator refernce from milk seperator

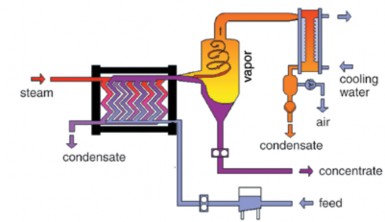

Animal Blood Plasma Concentration

The seperated plasma contain more than 90% of water, it is profitable step to evaporating some water before go futhermore processing. in some application, where liquid or freezing plasma be added, may result too high content of water in the final product.

In the beginning the falling film evaporating method is the only one can be used for blood plasma concentration equipement.

Blood concentration equipemnt

Current the membrance method have been developed to be used in plasma concentration equipement. As edible blood indutry is quite small to developing new technique, therefore most of technique are from milk-, diary, and pharmaccutical industry.

Plasma membrance concentration equipment

Freezing and Drying Equipment

Consider of preservation, the most be used methods are freezing and drying. typical flake ice freezing is used for freezing precess,

Flake Ice Frezzing Machine

Drying Equipment: Spray drying of plasma and hemoglobin have been used over 70 years. 1Kg dried plasma need 10~12L liquid plasma, and 1Kg dried hemoglobin need 2.5~3L of liquid products. some kind of spray drier can bring lots of draw backs, so when selected those drier type should be much careful.

Sray Drier

Spray Dryer Equipment

Edible Blood Products

The approval blood can be directly used for edible blood products, typical processing steps are Collection->Filter->Air seperator->Mix->Form and packaging->Sterilization.

- After collection the blood, using the 20# filter net to seperate the solid blood black. and mix with the salt.

- Air Seperator, using vaccum or heating etc. method to let the air which contain in the blood out. if using the vaccum, the reference blood temperture 40°C, Vaccum 0.08~0.09MPa, within 5min.

- Mix: mixing the coagulation agent with the blood, and quick filling into the packaging

- Sterilization: after sealing the packaging.

This is a comment to the webmaster. Your Animal blood processing equipment | Meater website is missing out on at least 300 visitors per day. I have found a company which offers to dramatically increase your traffic to your site: http://www.trumk.com/id They offer 500 free visitors during their free trial period and I managed to get over 15,000 visitors per month using their services, you could also get lot more targeted traffic than you have now. Hope this helps 🙂 Take care.