Abattior can gain more profit values by using blood collection equipment. However within Abattior, Animal be processing one by one continually, food safety and hygienic should be more careful. Let it be collected and handled according to EU fresh meat directive, then it can be used as edible blood.

Overview collection processing

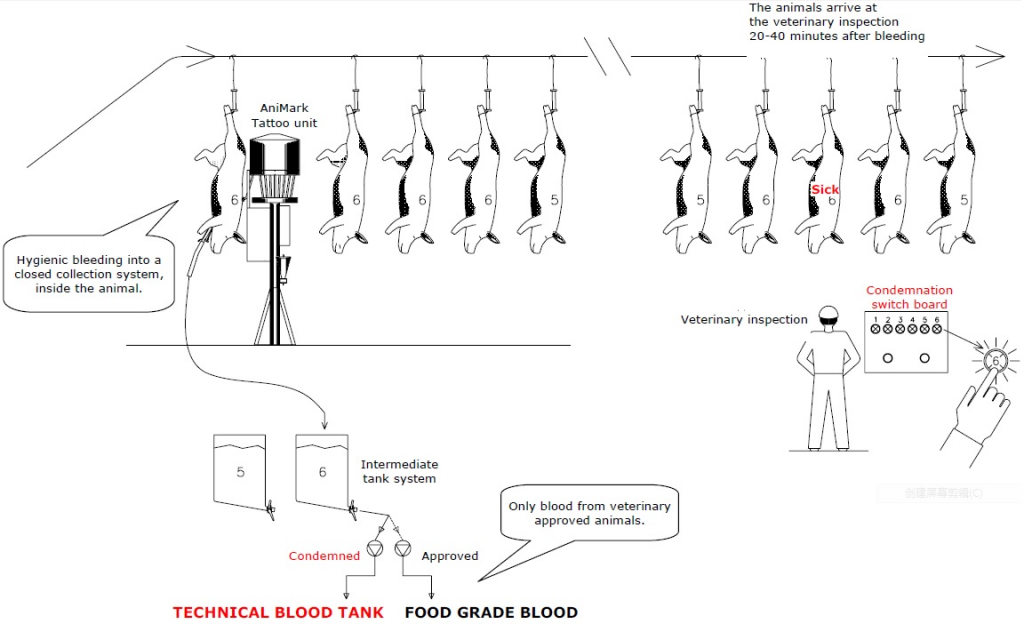

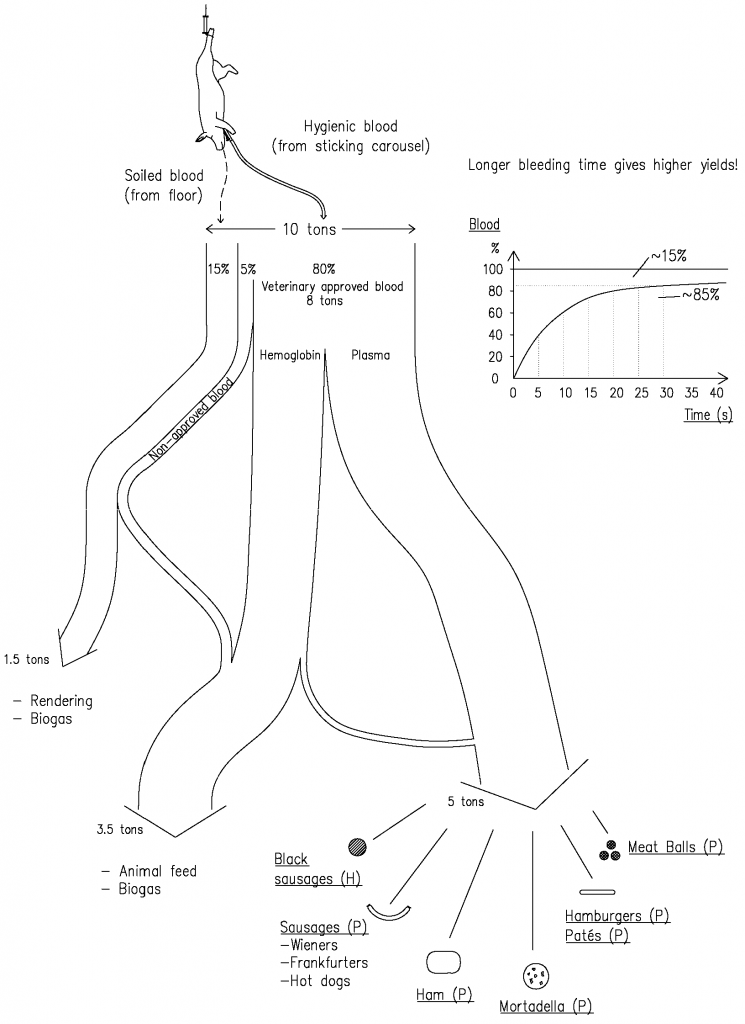

Animal blood is collected from the sticking conveyor / Sliding rail side, typical using the hollow knife with hose to suction to intermediate tank, after approval from the veterinary checking, the blood should be pump to blood vessels, or to condemned tank.

Blood Collection Equipment

Blood collection equipment

It’s tyipical using the rotation station with several hollow knife, when sticking, the blood can flow through the hollow knife, and Sodium citrate(or other Anticoagulants) be added at same time. The blood collection equipemnt selection should consider of the following factors.

- Size of animals.

- Killing line speed and number of sticker.

- Experience and skills of the sticker

- Method and efficiency of the stunning.

- Sharpeness of the hollow knifes.

- Layout of the wroking area.

- Health status of the animals.

The stickers are most important persons where quality and yield are considered. their mistakes cannot be repaired afterwards. To reducing the rejected blood, a pre-inspeciton and animal sort out should be considered. the cattle are in low rejected rate, according experience that it about 2~3% rejected blood volume for 10 pigs batch blooding.

For manual blood collection, it’s recommand handling within 90~180 PPH (pigs per hour), 20~75 CPH (Cattles per hour), of course the speed can be higher, but that will shorten the knife disinfection time, there have high capacity equipment available to handling the high speed slaughtering line, the sticker with a helper can reach 900PPH or 400CPH capacity.

Overview Abattior Blood equipemnt Profit

This introducing base on Anitec documentation

Recent Comments