The food production plant used to do cleanning with hoses, brooms, spray nozzles, scrapers etc.Although this scenario still occurs, most modern food plants now use the latest automated cleanning technology. And there are many systems available — mainly spray balls and advanced stationary nozzles — to meet every possible need. GLi delivery the world class of clean system from System Cleaners. Available products Clean Main Station, Chemical Pump Station, Clean Pump Station etc.

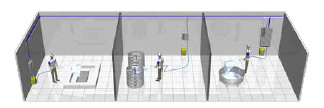

Decentral Manual Cleanning

This solution is using combine pump station with different clean station, the pump station supply the pressurised cleanning water, and each clean station can add on different cleanning agent during the cleanning process.

Flexible cleanning system

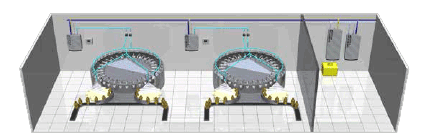

Automatic Central Cleanning

The automatic cleaning solution enables the cleaning of areas where access to carry out manual cleaning may be

difficult. Systematic, PLC-controlled cleaning ensures that the cleaning process is well documented, which is of particular benefit when striving to comply with ISO standards. Furthermore, cleaning times will often be reduced, thus enabling production time to be maximized. the cleanning technology used in food plants is a critical component of ensuring both food safety and the safety of workers. Today’s systems are effective, robust and an important support to food safety requirements and programs outlined in GFSI (the Global Food Safety Initiative) auditing schemes.

Automatic cleanning system, one click to run the preset steps

Mobile Station

The mobile cleaning unit, Voyager, can be used to cover large areas, generally with a considerable degree of flexibility. Voyager enables rinsing, foam application and disinfection to be performed.

The mobile cleaning unit, Voyager, can be used to cover large areas, generally with a considerable degree of flexibility

Recent Comments