Currently lots of slaughtering houses are still using the scalding tank for pigs, this scalding method have stable temperature, therefore the performance is good, howwever it’s also bring lots of disadvantage, higher carcoss temperature raising result higher PSE meat generated, and also bring cross contamination, scalding water in the lungs and chest cavity. the steam scalding tunnel is combined with seperated modules, which can let the temperature real, seperate control, and more accurate. in the same time , it can avoid the cross contamination and over scalding.

Over View Steam Scalding Tunnel

In Steam Scalding Tunnel, the inlet and outlet end are sealing with the rubber to provent the wind and heat leaking. between the inlet and outlet, there have standard modules and corner modules, typical the corner modules can be with inspection door or without.

Scalding Tunnel

Water Spray Scalding

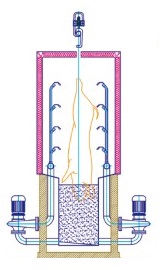

In general scalding tunnel have two type, spray water scalding and steam scalding. For spray water scalding, the pig head is dip into the hot water, and carcoss are be scalded by the spray water, compare with the scalding tank, it can avoid the cross contamination, over heated, scalding water in the lungs and chest cavity. so better hygiene. For steam scalding tunnel, tyipcal have two kind of structures, one mix the steam and water outside, one mix at jacket of scalding tunnel. MPS and Banns are using mix outside mode, and sFK is using mix at jacket side. mix jacket side could be better as the carcoss can get lower heating by adjusting the deflector, so the head can gain more heating which is the most difficult area for scalding.

|

|

| Out side mixing the steam with water | Jacket mixing the steam and water |

Design Notes for Sclading Tunnel

Saturated steam feeding

Scalding tunnel has excellent features energy-efficient, precise temperature steam rationing is to ensure effective guarantee scalding effect and energy efficiency. Based on the experience, each pig carcass scalding need about 1.5Kg steam, with the slaughter plant design capacity, you can estimate the amount of steam needed. With sufficient supply of steam, Another important component is the water atomizing nozzles, spray particle size, uniformity, are atomized wide angle is very critical factor which determines the degree of mixing of the steam the ability to form a saturated humid air at a temperature 58ºC ~ 65ºC range.

Steam circulation system

The circulartion system in scalding tunnel mainly to supply the heat energy. Steam heat the skin, and condensed into water, the condensed water infiltrate carcass skin and maintain same temperature by the continue circulartion steam. with effectively scalding, the pores open. So the wind speed in scalding tunnel is critical, select the appropriate speed is very important.

Temperature control unit

Most of scalding tunnel temperature taken PLC controlled through a feedback signal PT100 temperature sensor, PLC open the proportional steam valve according PID calculation, thus the heat entering the scalding tunnel is controlled. Real-time, automatic, precise temperature control in scalding tunnel.

naturally like your web-site however you need to take

a look at tthe spelling on quite a few of your posts.

Several of them are rife with spelling problems and I find it very bothersome to

inform the truth nevertheless I will surely ome basck again.

I know this web page provides quality dependent posts and extra stuff, is there any other web page which

gives these kinds of information in quality?

First off I want to say awesome blog! I had a quick question that I’d like to ask if you do not mind. I was curious to find out how you center yourself and clear your head before writing. I have had a difficult time clearing my mind in getting my ideas out there.

You are my inspiration , I have few web logs and very sporadically run out from to post .

It was hard to find your website in google.

I found it on 22 spot, you have to build a lot of quality backlinks , it will help

you to rank to google top 10. I know how to help you, just search in google – k2 seo tips

Attractive section of content. I just stumbled upon your web site and in accession capital to assert that I acquire in fact enjoyed account your blog posts.

Any way I’ll be subscribing to your augment and even I achievement you access consistently quickly.