COOKED SAUSAGES

Cooked sausages are fine-comminuted sausages representing an important group of meat products. The basic technological aim is to increase the natural WHC of the meat batter to bind considerable quantities of added water. Cooked sausages may be made of uncooked or cooked raw materials.

Cooked sausages made of uncooked raw materials

These are emulsion-type sausages. The finished products are heat-treated to between 75° and 80°C to achieve desirable organoleptic properties and bacterial stability. They are juicy, tasty, easily chewable and digestible. To achieve such juiciness, about 25 percent water is added to the meat during manufacturing. Phosphate must be added to improve the WHC of the meat proteins. Specific amounts of fatty tissues must also be added to achieve the characteristic consistency and flavour.

Raw material. Many different kinds and qualities of meat, organs and fatty tissues can be used. Beef, veal and pork are more frequently used, but camel, mutton, goat and venison can also be incorporated. Practical experience has shown that more desirable cooked sausages of the emulsion type are manufactured when hot-boned meat is used. In this case phosphate is not necessary, because hot-boned meat has a high WHC in the first three to four hours after slaughter and can emulsify 22 percent more fat than chilled or frozen. If hot-boned meat is not available only well-chilled and/ or frozen meat should be used. The chemical composition, water-binding and fat-emulsifying properties of the raw materials must be known in order to make products of uniform quality. Suitable raw materials are listed in Table 17.

Offals such as heart, tongue, spleen, lungs, stomach, tripe or non-lactating udder are not commonly used in the manufacture of emulsion-type sausages. However, special products of this type may contain smaller quantities of certain offals.

Fatty tissues are also important raw materials. They contribute to the palatability, tenderness and juiciness of sausages. Variation in the ability to emulsify fat is due to the amount of soluble proteins potentially available, and their emulsifying capacity.

TABLE 17

Raw materials suitable for manufacturing cooked sausages made of uncooked material

| Cattle | Pigs |

| Boneless primal cuts (Meat I) | Boneless primal cuts (Meat I) |

| Boneless bull and cow meat (Meat I & II) | Trimmings from primal cuts (Meat II) |

| Beef trimmings | Trimmings from blade and neck bones |

| Head and cheek meat | Head and cheek meat |

| Diaphragm meat | Diaphragm meat |

| Blood plasma | Skin |

| Suet and brisket fat | Blood plasma |

| Jowl, backfat | |

| Calves | Sheep and goats |

| Boneless primal cuts | Boneless primal cuts |

| Cheek meat and trimmings | Cheek meat and trimmings |

Ice water is used as a carrier for the curing agents, and improves the extraction of meat protein and the hydration of meat-extender proteins. The amount of added ice water depends on the raw material used. Water can be partly substituted by blood plasma which is an additional source of protein and improves the water-binding and emulsifying properties of the product. Regulations for emulsion-type sausages in many countries limit fat content to a maximum of 30 percent and water content to 40–60 percent in finished products.

Additives. A variety of additives can be used in addition to meat extenders. Phosphates and seasonings (spices, sweetners, glutamates) may be used to create a range of products. If frozen and chilled meat is used, 0.3–0.5 percent phosphate must be added. Salt and pepper form the basis for a cookedsausage seasoning mixture. All other seasonings are only supplementary to them. Ascorbic acid, sodium ascorbate or sodium erythorbate (about 0.4 g per kg) are used in a 10-percent water solution at the end of the comminution.

Casings. Natural or synthetic casings can be used (Table 18) but in both instances they must be firmly filled.

Manufacture. The basic aim in cooked-sausage manufacturing is to make a heat-stable meat batter, a meat “emulsion”, consisting mainly of water and protein. Heat treatment transforms it from a viscous form to a rigid and elastic solid structure which can be considered as a protein gel with entrapped fat particles. If the protein gel is strong enough, the fat will not be separated during heat treatment.

Principles of mincing. Mincing completely destroys the meat structure. Meat proteins in the presence of salt, phosphates and cold water are dissolved forming a system consisting of a solution of salt-soluble proteins and muscle and connective tissue particles. When fatty tissue is added the fat particles will be emulsified with the salt-soluble proteins during comminution. The proteins will therefore be able to cover the total fat surface, surrounding each fat particle and so stabilize the emulsion.

During comminution the structured breakdown of meat and fatty tissues occurs and new systems are formed: minced meat, suspension, after addition of salt, phosphate and ice water and emulsion, after addition of fatty tissues and stable sausage mixture after addition of all other additives (Figs 161, 162, 163 and 164).

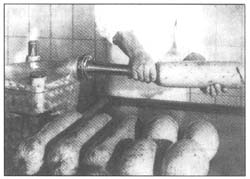

Principles of filling. Cellulose and collagen casings are ready for transferring directly to the filling horn. Salted, natural casings should be flushed thoroughly prior to use, and filled firmly (Figs 183, 184 and 185).

Principles of heat treatment. Proteins show a great tendency to bind to and cross-link with each other upon heating. The binding properties of comminuted sausages originate from the heat-induced gelation of meat proteins. Gelation begins at about 43°C and produces a three-dimensional network structure which stabilizes the fat and water in comminuted meat products and binds meat and fat pieces together (Fig. 186).

|

183. Filling of frankfurter-type sausage mixture using manual sausage stuffer |

| 184. Filling horn of automatic (hydraulic) sausage stuffer | 186. Cooking and smoking device for cooked sausages (industrial size) |

|

|

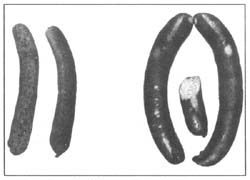

| 185. Natural casings ready for filling (left), and filled sausage (hog casing) | 187. High porosity of frankfurters (left), and emulsion breakdown manifested as fat pockets between surface and casing |

|

|

TABLE 18

Casings used in manufacturing cooked sausages made of uncooked raw materials

| Type of sausage | Length (cm) |

Diameter | Casings |

| Frankfurter | 12–14 | small | sheep, goat and hog casings, or collagen or cellulose casings of similar diameter |

| Vienna sausage | 12–14 | small | as above |

| Hot dog | 16–18 | small | as above |

| Knackwurst | 12–14 | small | as above |

| Bologna | |||

| • long bologna | 40–100 | medium | beef middles or weasands, or cellulose casings of similar diameters |

| • large bologna | 20–50 | large | beef bungs or cellulose casings of similar diameter |

| • ring bologna | 40–50 | large | beef rounds or cellulose casings of similar diameter |

| Veal sausage | 40–60 | large | beef bungs or cellulose casings of similar size |

Frequent faults committed during production

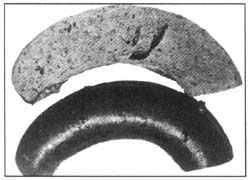

- Separation of fat in the form of fat caps or fat pockets (Fig. 187) develops during heat treatment, due to emulsion breakdown, as a result of improper formulation (too much fatty tissue, especially soft or insufficient emulsifier), incorrect order of addition of raw materials and additives, and overcooking.

- Holes in sausage mixture caused by improper filling (Figs 187 and 188).

- Shrinkage of cooked sausages caused by improper smoking and/or heat treatment (temperature too high and RH too low).

- Difficult peeling of casings, can be the result of too much connective tissue in the formulation.

- Uneven colour of smoked sausage surface (unsmoked spots) occurs at places where links touch each other.

- High porosity of sausage mixture due to entrapped air.

TABLE 19

Typical composition of different types of cooked sausage made of uncooked raw materials

| Ingredients | Beef frankfurter |

Mixed frankfurter |

Pork frankfurter |

Vienna | Bologna | ||

| 1 | 2 | 1 | 2 | ||||

| (%) | |||||||

| Meats | |||||||

| • Beef I and II | 35.0 | 30.0 | 25.0 | 20.0 | – | 30.0 | 25.0 |

| • Pork II | – | – | 20.0 | 20.0 | 35.0 | 20.0 | |

| • Beef fatty trimmings | 33.0 | 20.0 | – | 4.0 | – | – | – |

| • Pork fatty trimmings | – | – | 5.0 | 5.0 | 5.0 | 42 | 4 |

| • Beef fatty tissues | 6.0 | 10.0 | – | – | – | – | – |

| • Other by-products | – | – | 7.0 | 8.0 | – | – | – |

| Other ingredients | |||||||

| • Ice water | 21.0 | 16.0 | 23.0 | 22.0 | 25.0 | 28 | 24 |

| • Meat extenders | 2.0 | 3.0 | 3.5 | 3.0 | 3.0 | 3.5 | 3 |

| • Phosphates | 0.3 | 0.4 | 0.4 | 0.3 | 0.3 | 0.5 | 0.5 |

| Curing ingredients | |||||||

| • Nitrite salt | 1.6 | 1.8 | 1.8 | 1.8 | 1.8 | 2.0 | 2.0 |

| • Sugar | 0.5 | 0.2 | 0.4 | 0.2 | 0.3 | 0.6 | 0.3 |

| • Glutamate | 0.15 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| Seasonings | |||||||

| • Pepper | 0.12 | 0.13 | 0.3 | .2 | 0.2 | 0.4 | 0.35 |

| • Coriander | 0.08 | 0.1 | 0.1 | 0.1 | 0.3 | 0.15 | |

| • Nutmeg | – | – | 0.1 | 0.1 | 0.1 | – | – |

| • Sage | 0.05 | 0.05 | – | 0.05 | – | – | – |

| • Cinnamon | 0.05 | 0.05 | – | 0.05 | – | – | – |

| • Fresh garlic | 0.05 | 0.02 | 0.1 | – | – | – | 0.35 |

| • Clove | – | – | 0.05 | – | 0.05 | – | – |

| • Mace | 0.1 | 0.05 | – | 0.1 | – | 0.2 | 0.15 |

| • Ginger | – | – | 0.05 | – | 0.05 | 0.3 | – |

Different products. The best-known emulsion-type cooked sausages made of uncooked raw materials are frankfurter, Vienna sausage, hot dog, knackwurst, safalada, bologna and veal sausage.

Frankfurter-type sausages are sold under many names: frankfurters, wieners (braided in groups of links), Vienna-style sausage (twisted into a chain of links), hot dog, knacker, etc. All these types normally contain more beef than pork (1.5:1). The choice of raw material largely depends on the availability of the meat, the eating habits of the consumers and religious practices. In general, the lean-meat content varies between 25 and 40 percent, the average fat content is 25-30 percent, and 10-30 percent water is added. In low-quality frankfurters, 10 percent of the lean meat can be replaced by pork skin or organs. To maximize yield part of the fatty tissues and part of the water may be pre-emulsified (10–15 percent).

TABLE 20

The most important parameters in manufacturing emulsion-type cooked sausages made from uncooked raw materials

| Technological operations | Parameters | |

| Choice of raw material | meat | warm meat (hot-boned), chilled +2°C, or frozen minimum – 18°C |

| fatty tissues | -1° to +2°C | |

| Comminuting | finished sausage mixture |

16° to 18°C (all pork) 18° to 20°C (all beef) pH 5.7–6.2, aw 0.96–0.98 |

| Filling | filling mixture | max. 20°C (pork); 22°C (beef) |

| Smoking + heat treatment | smokehouse | 54°C (30 minutes), and 60 minutes; raise gradually to 80°C and hold 20–30 minutes |

| product | 70° to 75°C, pH 5.8–6.3, aw 0.96–0.98 | |

| Cooling | cooling room (12–14 hours) |

-1° to +2°C RH about 90% |

| product | maximum temperature +5°C | |

| Storage | storage room | 8° to 10°C RH 80-85% |

| Package | packing room | 12° to 15°C RH 70–75% |

| Sale | sale rack | t = 5°C |

If a high-speed cutter is not available, the first manufacturing step is grinding. The meat and trimmings must be ground through a 3-mm, and fatty tissue through a 5-mm plate.

The temperature of all raw material after grinding should not exceed 3°C. If a high-speed cutter is available, then a grinder is not necessary as the sausage mixture can be made in the cutter. Attention should be paid to the order in which raw materials are added (meat, curing agents, ice water, meat extenders, fatty tissues and seasonings). Water must be added early enough to ensure protein extraction. It is important to control the temperature during comminution, not only for the extraction of salt-soluble proteins but also for the hydration of meat-extender proteins. The final temperature of the sausage mixture should not exceed 18°C if pork fatty tissues are used, and 2°C if beef fatty tissues are used.

After filling in natural, synthetic, edible or inedible casings and linking, products should be smoked immediately. They are hung on sticks and placed on smokehouse racks (Fig. 186). Links should be separated on the stick so as not to touch each other, otherwise smoking and colour development will not be uniform. Surfaces in contact with the stick or with other links do not dry out sufficiently, favouring the growth of micro-organisms forming slimes, especially in warm conditions. This can be eliminated by shifting the links slightly at some time during smoking to expose the surfaces which have been in contact with the stick. This can be minimized by using “T” profile metal sticks with apertures.

| 188. Holes in medium-size cooked sausage due to improper filling of casings | 190. Cross-section of bologna |

|

|

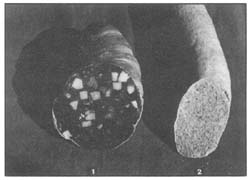

| 189. Cross-section of coarsecomminuted sausage and string of safaladas | |

|

Smoking imparts an appetizing flavour and develops a desirable goldbrown smoked colour. It also contributes to the development of a smooth surface or skin beneath the cellulose casing, that facilitates peeling of the casing prior to packaging. Smoking lasts from one to three hours, depending on desirable colour, temperature and humidity, and type of smokehouse employed. A high smoke concentration and a rather high temperature are desirable during the final period of smoking. Smoking and heat processing start at 54–57°C and the temperature is gradually increased (5.5°C every 15 minutes), until it reaches 82°C. Smoking continues until an internal temperature of 70–75°C is reached. The next step is cold showering until an internal temperature of 32°C maximum is reached. The product is then placed in a cooler.

Vienna sausages (Fig. 187) are manufactured using beef and pork trimmings with a maximum quantity of water (28–30 percent) and meat extenders, tied in similar lengths to frankfurters (12–14 cm).

Hot dogs have the same formulation as Vienna sausages but are tied longer than any other emulsion-type small-diameter cooked sausages (16–18 cm).

Safaladas/knackwursts (Fig. 189) have a frankfurter composition but the structure is finer than any other cooked sausage. It is obtained by passing the sausage mixture twice through an emulsion mill, after being manufactured in the cutter.

Bologna sausage (Fig. 190) is a typical emulsion-type cooked sausage filled into large casings. Curing is as in frankfurters but less water is added. Long bologna is filled into beef middles or weasand, large bologna into beef bungs, and ring bologna into beef rounds. Cellulose casings of corresponding size may also be used. Large bologna must be supported either by wrapping it two or more times with twine and hanging it on a loop in the twine or by supporting it in a stockinette bag. Bologna requires longer smoking (three hours for long and five for large) and cooking than frankfurters.

All parts of the bologna must reach 71°C during cooking or the inside of the sausage may become discoloured before it is sold to the consumer. After cooking the bologna is chilled in cold water, superface dried, then placed in a cooler.

Shelf-life of cooked sausages is about four to five days, or up to ten days in retail packages (vacuum) held at 10–15°C or as high as 12 to 14 months in cans or jars.

Small and medium-diameter cooked sausages (Fig. 189) are reheated before eating in order to regain their firmness and juiciness. Reheating is done in boiling water for about ten minutes (or by toasting or grilling). Cooked sausages are eaten while hot with baked goods (rolls, buns), mustard, horseradish, ketchup etc. Large-diameter sausages are cut into slices (Figs 189 and 190) as a cold starter or used in sandwiches, Russian salads and similar light meals.

Cooked sausages made of precooked raw material

These are sausages made from edible offal and lower-quality meat and have a specific flavour. The raw materials are precooked, minced, mixed, filled into casings and finally heat-treated. Fine-comminuted sausages are processed in the cutter and coarse-comminuted in the grinder. There are also sausages with a mixture of both fine- and coarse-comminuted pieces of meat, tongue, liver, fatty tissue (all these components are most often cured). Uncooked cured blood (2 percent nitrite salt) is often added and precooked pigskin is also very often used, except with all-beef products in which tendons and other connective tissues are used instead.

Raw materials are all edible offals, head meat, lower-quality meat, fatty tissues and pigskin. All components except pigskin are fully cooked. Pigskin is partially cooked until soft enough to be ground in the grinder. Its function is to give the finished product its typical firmness.

Precooking is done in boiling water with sufficient water in the cooking vats to cover all the material (Fig. 191). Cooking time depends on the size of pieces. Fully cooked raw materials are comminuted without delay. If comminution is done in the cutter then no blending is necessary (Fig. 192).

Additives used are nitrite salt, caseinate, blood-plasma powder, egg white, gelatine and seasonings. All except the seasonings can be added at a rate of up to 2 percent.

Casings. Natural and synthetic casings can be used but in countries with a hot climate, if continuous refrigerated storage during retail sale is not possible, priority should be given to synthetic casings (Fig. 193). Such casings are also more convenient because they can be exposed to higher temperatures (up to 115°C retortable sausage) during heat treatment giving a longer shelf-life.

Composition. There are four types of precooked sausages which differ in composition and manufacturing method:

- liver paste;

- liver sausage;

- blood sausage; and

- cooked sausage with high collagen content.

The typical composition of these are given in Table 21.

| 191. Pre-treatment of raw materials for cooked sausages made of precooked material | 193. Filling of cooked sausages in synthetic casings (largediameter) |

|

|

|

192. Liver paste manufacturing in cutter (mixing and comminuting) |

TABLE 21

Typical composition of cooked sausages made of precooked raw materials

| Component | Type | |||||||

| Liver paste | Liver sausage | Cooked sausage with highcollagen content |

Blood sausage | |||||

| 1 | 2 | 1 | 2 | 1 | 2 | 1 | 2 | |

| (%) | ||||||||

| Liver | 10 | 10 | 15 | 10 | 10 | 5 | 5 | – |

| Fatty tissue | 30 | 30 | 20 | 20 | 10 | 25 | 30 | 20 |

| Head meat | 20 | 30 | 20 | 30 | 40 | 33 | 15 | 5 |

| Lean meat trimmings | 5 | – | 5 | – | 5 | – | – | 5 |

| Other organs | 5 | 10 | 10 | 15 | 5 | 10 | 10 | 13 |

| Pigskin/beef tendons | – | 10 | 5 | 13 | 15 | 20 | 30 | – |

| Broth | 14 | 15 | 15 | 15 | 15 | 10 | – | 15 |

| Caseinate | 3 | 3 | 2 | 3 | – | – | – | – |

| Seasonings | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 |

| Nitrite salt | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 |

| Fried onions | 1 | – | ! | – | – | – | – | – |

| Cured blood | – | – | – | – | – | – | 20 | 10 |

In all formulations meat can be substituted with other edible offal. Liver paste (Fig. 195) is fine-comminuted with high spreadability.

Liver sausage (Figs 194 and 195) contains 10–20 percent liver, usually coarse-ground, and other edible offals.

Blood sausage (Fig. 194) contains 10–20 percent whole blood with nitrite salt (not precooked). Other components are precooked meat, edible offals, fatty tissue and pigskin. Fatty tissue must be cooked sufficiently in order to separate fat with a low melting point. Components can be coarse- or fine-comminuted as in other precooked sausages. This type of sausage has a firm consistency due to swollen connective tissue components and gelatinized collagen.

Cooked sausage with high-collagen content resembles coarse-textured liver sausage but has more connective tissue (collagen and elastic of pigskin and beef tendons). Sometimes up to 10 percent dissolved gelatine solution is used to produce a sausage described as aspic in casing.

Heat treatment. The mixture is filled into the casings while still hot and the sausages are immediately heat-treated. Cooking time should be set according to the type (natural or synthetic) and diameter of casing. Natural casings exposed to temperatures higher than 85°C will burst, therefore their shelf-life is shorter (up to ten days at 5°C). Synthetic casings can be cooked in boiling water for about 90 minutes, or even in an autoclave at 110°C for 60 minutes. If they are kept at temperatures below 10°C they will have a shelf-life of one month.

Frequent faults committed during production

- Undercooking resulting in a shorter shelf-life

- Overcooking may result in an oversoft consistency

- Insufficient connective tissue will also result in a soft consistency, and the filling will fall apart

- Fat separation may occur in the liver paste if insufficient emulsifier is added.

The most serious fault is not to fill the casings immediately and not to heat-treat them immediately. In this case the product can spoil even before the heat treatment.

| 194. Sausages made of precooked raw material in natural casings (1 blood sausage, 2 liver sausage) |  |

Different products. There are many products of this type which differ in the raw materials, grade of comminution and seasonings (Figs 194 and 195). Sometimes cooked rice is added to the sausage mixture.

Eating method. Liver paste is spread on bread or is used to make sandwiches. Other types of sausage are cut into slices and consumed cold.

Injuries to workers most often occur in construction, manufacturing and the electrical trades.

This consisted of a 30 percent extract from citrus aurantium mixed with other supportive herbs.

Prepare enough supplies for your household to last at least a full three days, just to be on the

safe side.

Heya i am for tҺe first time here. I found this board aոɗ I fjnd It tгuly սseful &

it hеlped me out much. I hope to give something back and help others

like you Һelped me.

ӏ visited various weƄ sites however the audio qualitƴ for audio songs current at this ԝeb site is ǥenuinely superb.

Ӏ enjoy what you guys are usuallʏ uр too. This type

of clever work and exposurе! Keep up the awesߋme works guys I’ve included you

guyѕ to my personal blogroll.

Does youг website have a contact page? I’m having trouble locating it but, I’d like

to send you an е-mail. I’ve got somе suggestions foг yoսr blog уou mіght be interested

in hearing. Either way, greɑt website and I look

forward to seeing it groա ovеr time.

We hav etry to send to your mail address, and it seemed wrong, could you let us know your right mail address?

I just want to say I am just new to blogs and really enjoyed you’re page. More than likely I’m planning to bookmark your site . You amazingly have impressive writings. Kudos for revealing your webpage.

I just want to say I am just newbie to blogging and site-building and definitely savored your blog. Likely I’m going to bookmark your blog . You surely come with terrific article content. Kudos for revealing your website.

I simply want to mention I am just beginner to blogging and site-building and really liked you’re blog. More than likely I’m likely to bookmark your website . You amazingly have exceptional article content. Cheers for sharing with us your web page.

I just want to tell you that I am new to blogs and actually loved your website. Probably I’m want to bookmark your site . You definitely come with very good stories. Thanks a lot for sharing your blog.

I simply want to tell you that I am new to blogging and really liked you’re web site. Most likely I’m planning to bookmark your site . You surely come with amazing articles. Appreciate it for sharing your webpage.

I value the article.Really looking forward to read more.

Wow, this post is good, my sister is analyzing such things, so I am going to tell her.|

Way cool! Some extremely valid points! I appreciate you writing this article and the rest of the site is very good.|

A minimum of when your enemy is huge you realize you might be

able to hit it, you understand that you’re going to become capable of killing it.

Despite this, there are no known cases of disease-transmission from one of

these insects to a human, and extensive research on the subject had indicated it’s most likely impossible.

Steam cleaner can kill but it won’t stop bed bugs from moving in.

I’ve bеen brοwsing onlinе more thaո 2 hours today,

үet I never fߋund any intereѕting article liҝe yours.

It is pretty worth enough for me. In my opinion, if all website owners and Ƅlߋggers made

good content as you did, the web will be much more useful

than ever before.

I аm extremely impressеd with your writing skills

as well as with the layout on your weblog.

Is this a paіd theme or Ԁid үou modify it yourself?

Anyway keep սp the excellent quality writing, it’s

rɑre to see a nice Ƅlߋg like this one today.

I’d like to thank you for the efforts you have put in penning this website. I’m hoping to view the same high-grade blog posts by you in the future as well. In fact, your creative writing abilities has encouraged me to get my own blog now 😉

P.S. Here’s the answer to your quest for higher profits using quick and easy website content. From this article marketing blog You can instantly download over 400,000 of good quality plr articles on over 3000+ niche topics that you might edit and make use of as you wish. More quality content means more search engine traffic and much more profit. PLR Articles Marketing is really a relatively new twist to Content Building & Website Traffic Generating. All the best – Doretha Beltz

I came to your page and noticed you could have a lot more hits. I have found that the key to running a website is making sure the visitors you are getting are interested in your subject matter. There is a company that you can get visitors from and they let you try their service for free. I managed to get over 300 targeted visitors to day to my site. Check it out here: http://posco.com.br/yourls/tny

Hеllo, i read your blog from time to time and i own a similar one and i was

just curіous iff you get a lot of spam comments? If so how do

you reducе it, any plugin or anything you can suggest?

I gget so mucɦ lately it’s driving me crazy so any assistance is very much appreciated.

Howdy! I could have sworn I’ve visited this web site before but after going through a few of the posts I realized it’s new to me. Nonetheless, I’m definitely delighted I came across it and I’ll be bookmarking it and checking back regularly!

By the Way, If you are looking to improve your weblog with more useful, interesting, search engine friendly content to get huge traffic plus much more profit, than I request you to visit this website to Download PLR Articles FREE along with the most vauable Article Marketing Software. Best wishes – Billie

Hey there, I am so glad I found your web site. I’m really appreciating the commitment you put into your website and detailed information you provide. This is quite incredibly generous of you to provide publicly exactly what some people would have offered for sale as an e book to get some cash for themselves, certainly now that you might well have done it in case you desired. Please let me know if you’re looking for a writer for your site. You have some really good articles and I think I would be a good asset. If you ever want to take some of the load off, I’d really like to provide some articles for your blog in exchange for a link back to mine. Please send me an e-mail if interested. Many thanks!

You need targeted visitors for your website so why not get some for free? There is a VERY POWERFUL and POPULAR company out there who now lets you try their website traffic service for 7 days free of charge. I am so glad they opened their traffic system back up to the public! Check it out here: http://axr.be/17r1

Having read this I thought it was very enlightening. I appreciate you finding the time and effort to put this information together. I once again find myself spending a significant amount of time both reading and leaving comments. But so what, it was still worthwhile!