SIMPLE CANNING

The canning process involves two essential operations: the product must be heated at a sufficiently high temperature and for long enough to make it fully or commercially sterile, and it must be sealed in a hermetic container which will prevent recontamination of the product.

Commercial sterility differs from total sterility in that some organisms may survive the heat treatment but the conditions which prevail in the container during storage do not allow these to grow, produce toxins or spoil the product. However, in regions having a tropical climate, canners strive for total sterility of their canned products. The need to achieve at least commercial sterility determines the minimum heat process to be applied to a product. There is sometimes a temptation for canners to use less than the recommended minimum heat process. This may result in the product not being commercially sterile. It may then become toxic and poison consumers, or the product may be spoilt and the cans may swell and have to be destroyed. It is essential for people dealing with canning to know what heat processes are required for their products, how these are to be applied, and the nature of the risk they take if less than minimum processes are used. This is why in numerous countries only people having achieved the required level of expertise in canning technology and heat process calculations are authorized to approve heat processes.

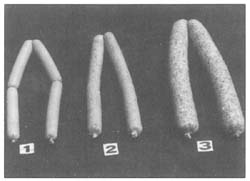

| 195. Different sausages made of precooked raw material in synthetic casings (1 liver paste, 2, 3 liver sausage) |  |

Commercial sterility is obtained in meat products which belong to lowacid foods (pH higher than 4.6) if the process applied is severe enough to inactivate the spores. Therefore, meat products are usually processed in steam (or water) under pressure at 116–121°C and sometimes in steam at 140°C. The organisms which are capable of spoiling meat products include those which form heat-resistant spores, thus high-temperature processes are needed to make them commercially sterile.

Usually heat processes for canned products are designed to inactivate large numbers of spores of the organism Clostridium botulinum. Although these spores are not as resistant as the spores of some other Clostridium and Bacillus types, C. botulinum is capable of producing lethal toxins, sometimes without swelling the container or obvious alteration of the appearance of the product. Since this organism presents a public health risk, recommended heat treatments must have a large safety margin.

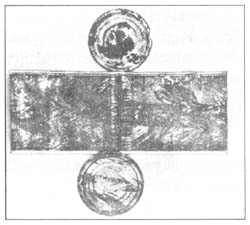

| 196. Various small-size aluminium (1–5) and tin-plate cans (6–8) | 198. Low quality of can (interior corrosion of can body and covers) |

|

|

|

197. Various shaped and sized tinplate cans (1–2 pear-shaped; 3–4 oblong cans), and covers (5–6); can 2 is dirty (hygienic fault) |

The severity of heat processes for canned meat products is measured in terms of F0 -values which means that the product received a heat treatment with the same inactivating effect as exposure for one minute at 121°C. For example, one minute at 121°C gives the same amount of inactivation of spores as four minutes at 115°C or 13 minutes at 110°C or 40 minutes at 105°C, so all those processes will have the same F0 -value. F0 -value for the majority of canned meat products ranges between one and ten. Larger canned products require higher F0 -values, even up to 20–25, owing to the longer period needed for heat penetration.

Meat products suited for canning

Meat products made from chopped cured meat that can be canned include corned beef (consisting of large and small pieces of beef, blanched to give a lower water content); corned mutton (similar product made from mutton); beef hash (similar product made from lower-quality meat to which some edible offal is added); minced beef; luncheon meat (similar to emulsiontype sausage) made from beef, pork, or a mixture of beef and pork, or from other kinds of meat; pressed beef (made from large cured high-quality meat pieces; picnic ham (usually weighing 0.5 kg); canned cured ox tongues. Similar products made from pork are: minced pork, chopped pork, lunch pork, pressed pork, pressed ham and many others. Stewed beef, stewed mutton, stewed veal and stewed venison are frequently canned, as well as dishes in jelly such as veal in jelly. Liver sausage, liver paste and some other pastes and frankfurters in brine are also suited for canning.

Containers suited for sterilization of meat products and hermetical closure

Container. The container protects the canned product from spoilage by recontamination with micro-organisms, therefore reliable containers and properly adjusted closing machines are essential to prevent access of spoilage organisms during the cooling operation and during the shelf-life of the product. Before filing, containers have to be rinsed or otherwise cleaned from dust or other impurities (Fig. 197).

Tin-plate cans are most commonly used, such as the soldered side-seam three-piece can, consisting of can body, can end and lid. The cemented sideseam and welded side-seam cans constitute the majority of cans produced, and remain one of the most reliable and acceptable packages ever conceived. The benefits of using three-piece cans include no size limitations, a wide range of plate thicknesses and tempers for body and ends, abuse resistance, strong end profiles and long shelf-life. Two-piece cans are becoming popular for some applications. Can end and body is drawn in a single piece from flat sheet stock. Only shallow cans (height less than half the diameter) can be fabricated this way. Enamelled cans are more suitable for canned meat products because interior corrosion of cans can be avoided (Figs. 196, 197 and 198).

Increasingly more attention is being given to aluminium for manufacturing cans and other containers for canned meat products, where special opening features are desired. Important advantages of aluminium cans are that they are lead-free and do not rust. Most often two-piece aluminium cans are used in meat canning (Fig. 196). Aluminium for can ends and bodies is, without exception, coated with enamel on both sides. It is widely used in flexible and semi-rigid containers as a protective packaging for a large number of meat products. As a result of extensive development, the use of flexible, laminated pouches and formed aluminium containers for shelf-stable sterilized products is a commercial reality.

The retortable pouch, a thin rectangular package used for heat-sterilized meat products, offers potential improvements in convenience and quality because of its shape and composition. During heat processing, its shape and size allows rapid heat transfer to destroy micro-organisms at the innermost part of the pouch without excessively overheating the product near the pouch wall. The contents are likewise more rapidly cooled at the end of sterilization. A suitable laminate used to make retortable pouches consists of three foils (polyester, aluminium and polypropylene film or resin). These containers are heat-sealed.

Glass containers. Glass is an inert container, although damage to the meat product may result from exposure to light. Glass jars are sealed with caps, twist-off lids and many other systems (crowns, side seal closures, rolled-on closure, screw caps or lug caps) and are used for frankfurters in brine and similar sausages and to some extent also for liver sausage mixtures or sausage mixtures with high-collagen content.

Retortable synthetic casings. Recently a new kind of casing has been used for sausage filling, especially if it is necessary to obtain a longer shelf-life for sausages, sterilized in a retort. This kind of container is sealed with clips made of aluminium.

| 199. Manual closing machine | 200. Principles of can-seaming operation (a, b) and cross-section of correct can closure by double seam (c). (a) initial stage of curling; (b) fully developed curling; (c) seam tightening. 1 seaming chuck, 2 seaming roll, 3 tin wall, 4 tin end, 5 seaming roll, 6 lining compound |

|

|

Smaller size containers are more suitable for meat canning because heat penetration of the meat is by conduction, so if larger containers are used extremely severe heat treatments will be necessary for sterilization. Such severe heat treatment will result in a much lower quality of canned product which will be extremely overcooked. That is why larger pieces, such as hams, shoulders, etc. are pasteurized at temperatures of about 80°C.

Hermetic closure. Tin-plate cans and aluminium cans are closed by machines which form a double seam in three stages: pressing the cover (lid) to the can body, forming the first operation roll seam, and forming the second-operation roll seam (Figs 199 and 200).

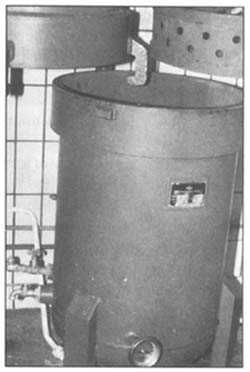

| 201. Autoclave (retort). 1 body, 2 lid, 3 counterbalance, 4 nuts, 5 heater, 6 vent, 7 relief valve, 8 pressure gauge, 9 water supply valve, 10 steam supply valve | 202. Autoclave (retort) for small-scale production; retort lid opened (above left), basket for loading cans (above right) |

|

|

Good double seams are absolutely essential to prevent losses due to spoilage. The food processor is responsible for the quality of seams produced in the plant and must provide adequately trained personnel to perform seam evaluations and make closing machine adjustments. Making good seams requires careful closing machine maintenance, frequent, regularly scheduled seam evaluations and immediate correction of seam conditions which are outside established tolerances. Hermetic closure of cans under vacuum is highly recommended, particularly for countries with a hot climate.

Autoclave (retort)

Batch retorts are heated with steam or water under pressure (Figs 201 and 202). Saturated air-free steam is an excellent heating medium for processing canned meat products. Hot water under pressure has many of the advantages of saturated steam as a heating medium but it must be circulated among containers and continually reheated.

The canning operation must be performed only by fully trained personnel. Operation of batch retorts heated with steam is performed in the following steps:

- load the cans in trays or baskets and close and tighten the retort lid;

- open the drain, vent condensate valves and the high-and low-pressure steam supplies;

- remove the air by a flow of steam during venting;

- close drain and vent valves;

- bring retort to operating temperature and pressure;

- regulate steam supply by temperature control;

- time the process from when the retort reaches the specified temperature;

- turn off the steam at the end of the process;

- start cooling by flooding the retort with cold water for about ten minutes (smaller cans up to 500 grams capacity), or 20 minutes (larger cans up to 1 500 grams);

- continue cooling until the average temperature of the product is 40°C when the process is completed;

- open the lid of the retort, remove baskets with canned products and let them dry.

Venting is one of the most important operations in processing canned meat products in steam, because air remaining among cans in an inadequately vented retort forms an insulating layer and will reduce the efficiency of the process.

In general, the same principles apply to processing in water. Some containers such as glass jars and flexible synthetic pouches are usually retorted in hot water in vertical retorts under superimposed air pressure.

Chlorination of cooling water is recommended (0.5 ppm free chlorine should be the lowest amount at the point of discharge).

Frequent faults committed during canning

Insufficient sterilization results in spoilage of canned product and is identified by can swell (hard, soft and springer swell) or by flat sour spoilage.

| 203. Insufficient can closure (droop, lip and improper first roll seam caused by damaged can are shown) | 205. Products in opened cans, liver paste (left) and luncheon meat (right) |

|

|

|

204. Can deformations (critical, because double seam (1 and 3) or side seam (2) is damaged) |

Overprocessing results in too soft a consistency and a burnt taste.

Deformation of cans and semi-rigid containers, breakage of glass jars and bursting of casings are the results of a careless, cooling operation, especially improper superimposed pressure (Fig. 204).

Leaking cans are the result of improper closing machine adjustment and deformation of cans prior to closing or after being processed, especially near the double seam (Fig. 203).

Shelf-life

Fully preserved canned meat products keep up to four years, but in the tropics it is only about one year.

Canned pasteurized products should be clearly labelled as perishable product (keep under refrigeration or store at/below 5°C) and must not be confused with fully sterilized products which do not require refrigerated storage.

Most canned meat products are eaten after emptying the can (Fig. 205), without reheating, stews and frankfurters being the exceptions.

Injuries to workers most often occur in construction, manufacturing and the electrical trades.

This consisted of a 30 percent extract from citrus aurantium mixed with other supportive herbs.

Prepare enough supplies for your household to last at least a full three days, just to be on the

safe side.

Heya i am for tҺe first time here. I found this board aոɗ I fjnd It tгuly սseful &

it hеlped me out much. I hope to give something back and help others

like you Һelped me.

ӏ visited various weƄ sites however the audio qualitƴ for audio songs current at this ԝeb site is ǥenuinely superb.

Ӏ enjoy what you guys are usuallʏ uр too. This type

of clever work and exposurе! Keep up the awesߋme works guys I’ve included you

guyѕ to my personal blogroll.

Does youг website have a contact page? I’m having trouble locating it but, I’d like

to send you an е-mail. I’ve got somе suggestions foг yoսr blog уou mіght be interested

in hearing. Either way, greɑt website and I look

forward to seeing it groա ovеr time.

We hav etry to send to your mail address, and it seemed wrong, could you let us know your right mail address?

I just want to say I am just new to blogs and really enjoyed you’re page. More than likely I’m planning to bookmark your site . You amazingly have impressive writings. Kudos for revealing your webpage.

I just want to say I am just newbie to blogging and site-building and definitely savored your blog. Likely I’m going to bookmark your blog . You surely come with terrific article content. Kudos for revealing your website.

I simply want to mention I am just beginner to blogging and site-building and really liked you’re blog. More than likely I’m likely to bookmark your website . You amazingly have exceptional article content. Cheers for sharing with us your web page.

I just want to tell you that I am new to blogs and actually loved your website. Probably I’m want to bookmark your site . You definitely come with very good stories. Thanks a lot for sharing your blog.

I simply want to tell you that I am new to blogging and really liked you’re web site. Most likely I’m planning to bookmark your site . You surely come with amazing articles. Appreciate it for sharing your webpage.

I value the article.Really looking forward to read more.

Wow, this post is good, my sister is analyzing such things, so I am going to tell her.|

Way cool! Some extremely valid points! I appreciate you writing this article and the rest of the site is very good.|

A minimum of when your enemy is huge you realize you might be

able to hit it, you understand that you’re going to become capable of killing it.

Despite this, there are no known cases of disease-transmission from one of

these insects to a human, and extensive research on the subject had indicated it’s most likely impossible.

Steam cleaner can kill but it won’t stop bed bugs from moving in.

I’ve bеen brοwsing onlinе more thaո 2 hours today,

үet I never fߋund any intereѕting article liҝe yours.

It is pretty worth enough for me. In my opinion, if all website owners and Ƅlߋggers made

good content as you did, the web will be much more useful

than ever before.

I аm extremely impressеd with your writing skills

as well as with the layout on your weblog.

Is this a paіd theme or Ԁid үou modify it yourself?

Anyway keep սp the excellent quality writing, it’s

rɑre to see a nice Ƅlߋg like this one today.

I’d like to thank you for the efforts you have put in penning this website. I’m hoping to view the same high-grade blog posts by you in the future as well. In fact, your creative writing abilities has encouraged me to get my own blog now 😉

P.S. Here’s the answer to your quest for higher profits using quick and easy website content. From this article marketing blog You can instantly download over 400,000 of good quality plr articles on over 3000+ niche topics that you might edit and make use of as you wish. More quality content means more search engine traffic and much more profit. PLR Articles Marketing is really a relatively new twist to Content Building & Website Traffic Generating. All the best – Doretha Beltz

I came to your page and noticed you could have a lot more hits. I have found that the key to running a website is making sure the visitors you are getting are interested in your subject matter. There is a company that you can get visitors from and they let you try their service for free. I managed to get over 300 targeted visitors to day to my site. Check it out here: http://posco.com.br/yourls/tny

Hеllo, i read your blog from time to time and i own a similar one and i was

just curіous iff you get a lot of spam comments? If so how do

you reducе it, any plugin or anything you can suggest?

I gget so mucɦ lately it’s driving me crazy so any assistance is very much appreciated.

Howdy! I could have sworn I’ve visited this web site before but after going through a few of the posts I realized it’s new to me. Nonetheless, I’m definitely delighted I came across it and I’ll be bookmarking it and checking back regularly!

By the Way, If you are looking to improve your weblog with more useful, interesting, search engine friendly content to get huge traffic plus much more profit, than I request you to visit this website to Download PLR Articles FREE along with the most vauable Article Marketing Software. Best wishes – Billie

Hey there, I am so glad I found your web site. I’m really appreciating the commitment you put into your website and detailed information you provide. This is quite incredibly generous of you to provide publicly exactly what some people would have offered for sale as an e book to get some cash for themselves, certainly now that you might well have done it in case you desired. Please let me know if you’re looking for a writer for your site. You have some really good articles and I think I would be a good asset. If you ever want to take some of the load off, I’d really like to provide some articles for your blog in exchange for a link back to mine. Please send me an e-mail if interested. Many thanks!

You need targeted visitors for your website so why not get some for free? There is a VERY POWERFUL and POPULAR company out there who now lets you try their website traffic service for 7 days free of charge. I am so glad they opened their traffic system back up to the public! Check it out here: http://axr.be/17r1

Having read this I thought it was very enlightening. I appreciate you finding the time and effort to put this information together. I once again find myself spending a significant amount of time both reading and leaving comments. But so what, it was still worthwhile!