PRINCIPLES OF HEAT TREATMENT FOR NON-STERILIZED PRODUCTS

During processing many meat products are subject to specific heat treatment. The first task of heat treatment is to reach satisfactory shelf-life by reduction of micro-organisms. The second task is to obtain desirable organoleptic characteristics, to preserve nutritive value and improve digestibility of the product.

Reduction of micro-organisms

Bacteria are destroyed if exposed to sufficiently high temperatures for long enough. There is a direct relationship between bacteria survival and time of exposure to temperatures. As an example, if 10 000 000 bacteria (per ml) suspended in broth are exposed to heat (70°C), after the first five minutes 1 000 000 will survive (90 percent are destroyed), after the next five minutes the number of surviving will be 100 000 (again 90 percent are destroyed), and so forth.

This tenfold reduction in bacterial numbers between fixed time intervals is called decimal reduction. The time interval for decimal reduction varies between different bacteria and depends on the temperature applied. The number of bacteria present in a meat product just before the heat treatment (initial number) should be as low as possible so that a shorter time or lower temperature is needed to achieve a satisfactory shelf-life for the product.

As sausage fillings as well as most other meat products represent a very good medium for bacterial growth, they should immediately be exposed to heat treatment in order to prevent bacterial growth. It is also important to perform all operations as quickly as possible, and to maintain the highest hygienic standards so that the initial bacterial count remains as low as possible. The manufacturer must always bear in mind that bacteria grow very fast. Their number may be doubled every 20 minutes.

Organoleptic changes

These are caused by heat treatment (doneness, flavour, firmness, consistency and cured-meat colour development) are time-temperaturedependent processes. The basic effect of the heat treatment is coagulation of meat proteins. Between 70° and 80°C the majority of meat proteins are completely coagulated, forming a structural matrix which entraps fat and water droplets released during heat treatment. With coagulation of meat proteins, WHC is decreased and the meat loses a certain amount of water (thermal weight loss). Those structural changes of proteins are responsible for characteristic firmness of heat-treated products. Frankfurters have an elastic firmness, and on reheating prior to consumption become even more firm. Products containing connective tissue become more tender owing to solubilization of the collagen (gelling). Products such as paste which are in a liquid state prior to heating change for more viscous and spreadable consistency. Sausages made from larger meat pieces also attain a characteristic consistency. The exudate released during massaging or tumbling coagulates and binds the pieces of meat.

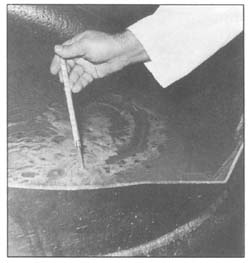

| 144. Temperature measurement in a cooking vat | 146. Simple cooking equipment with the movable vat |

|

|

|

145. Temperature measurement with thermometer in large-diameter cooked sausage (centre), during chilling by cold water (showering) |

TABLE 8

Influence of temperature and time of heat treatment on cured-meat colour development in bologna (diameter 90 mm)

| Temperature of heating medium | Time necessary to develop | |

| Pinkish (not stable) |

Red colour (stable) |

|

| (°C) | (min) | |

| 70 | 90 | 110 |

| 75 | 75 | 90 |

| 80 | 60 | 75 |

| 100 | 30 | 45 |

| 110 | 15 | 30 |

Such products (cooked hams, ham sausages) become sliceable. Heat treatment also makes products chewable.

In addition to these physical changes resulting from heat treatment, some biochemical reactions also take place which contribute to the typical flavour of heat-treated products. Many compounds present in the raw material are broken down by heat to produce the characteristic flavour. Fatty components give the meat product a distinctive flavour, specific to the animal species from which fat is obtained.

Cured-meat colour is not stable unless the raw product is heat-treated.

All these changes occurring during heat treatment give the product its typical overall sensation of doneness.

Duration of heat treatment

The duration of the heat treatment primarily depends upon the size and shape of the meat product. Treatment continues until the coldest point (innermost part) reaches the defined temperature. It is essential to check temperatures of the heating medium and of the innermost part of the products and to observe exact times (Figs 144 and 145).

TABLE 9

Heat treatment of different meat products

| Product | Temperature | |

| Heating medium | In product | |

| (°C) | ||

| Fresh sausages, hamburgers | 150–350 | 65–110 |

| Sausages made of uncooked raw material | 75–85 | 70–75 |

| Sausages made of precooked raw material | 80–98 | 85–90 |

| Canned cured hams, shoulders and loins | 75–85 | 70–75 |

Types of heat treatment

Heat treatment by dry heat is performed in special ovens (roasting) or on a gridiron (grilling). Meat loaves and similar products are roasted. Meat patties, hamburgers and fresh sausages are grilled.

Heat treatment by hotwater is the most common and is usually performed in large cooking vats. When applied to canned hams or ham sausages, it is called pasteurization (Figs 144, 145 and 146).

Heat treatment by steam is one in special steam cabinets and is in particular applied in cases when treatment in cooking vats is not desirable because of substantial losses of aroma and flavour of the products into the cooking water.

Frequent faults committed during heat treatment

Undercooking may be due to the temperature being too low, the time of treatment being too short, or both. The consequences are in a reduced shelflife due to spoilage and the possibility of food-poisoning. Spoilage results in a bad smell, discoloration, softened consistency and souring.

Overcooking results from either too high a temperature or too long a duration or both. The consequences are increased cooking losses, fat separation in some sausages, undesirable changes of flavour and a softer consistency.

General remarks

In order to keep the initial bacterial numbers as low as possible it is important to keep the temperature of the raw materials as low as possible before heat treatment. After filling sausages and mixing other meat products heat treatment must be applied immediately.

Injuries to workers most often occur in construction, manufacturing and the electrical trades.

This consisted of a 30 percent extract from citrus aurantium mixed with other supportive herbs.

Prepare enough supplies for your household to last at least a full three days, just to be on the

safe side.

Heya i am for tҺe first time here. I found this board aոɗ I fjnd It tгuly սseful &

it hеlped me out much. I hope to give something back and help others

like you Һelped me.

ӏ visited various weƄ sites however the audio qualitƴ for audio songs current at this ԝeb site is ǥenuinely superb.

Ӏ enjoy what you guys are usuallʏ uр too. This type

of clever work and exposurе! Keep up the awesߋme works guys I’ve included you

guyѕ to my personal blogroll.

Does youг website have a contact page? I’m having trouble locating it but, I’d like

to send you an е-mail. I’ve got somе suggestions foг yoսr blog уou mіght be interested

in hearing. Either way, greɑt website and I look

forward to seeing it groա ovеr time.

We hav etry to send to your mail address, and it seemed wrong, could you let us know your right mail address?

I just want to say I am just new to blogs and really enjoyed you’re page. More than likely I’m planning to bookmark your site . You amazingly have impressive writings. Kudos for revealing your webpage.

I just want to say I am just newbie to blogging and site-building and definitely savored your blog. Likely I’m going to bookmark your blog . You surely come with terrific article content. Kudos for revealing your website.

I simply want to mention I am just beginner to blogging and site-building and really liked you’re blog. More than likely I’m likely to bookmark your website . You amazingly have exceptional article content. Cheers for sharing with us your web page.

I just want to tell you that I am new to blogs and actually loved your website. Probably I’m want to bookmark your site . You definitely come with very good stories. Thanks a lot for sharing your blog.

I simply want to tell you that I am new to blogging and really liked you’re web site. Most likely I’m planning to bookmark your site . You surely come with amazing articles. Appreciate it for sharing your webpage.

I value the article.Really looking forward to read more.

Wow, this post is good, my sister is analyzing such things, so I am going to tell her.|

Way cool! Some extremely valid points! I appreciate you writing this article and the rest of the site is very good.|

A minimum of when your enemy is huge you realize you might be

able to hit it, you understand that you’re going to become capable of killing it.

Despite this, there are no known cases of disease-transmission from one of

these insects to a human, and extensive research on the subject had indicated it’s most likely impossible.

Steam cleaner can kill but it won’t stop bed bugs from moving in.

I’ve bеen brοwsing onlinе more thaո 2 hours today,

үet I never fߋund any intereѕting article liҝe yours.

It is pretty worth enough for me. In my opinion, if all website owners and Ƅlߋggers made

good content as you did, the web will be much more useful

than ever before.

I аm extremely impressеd with your writing skills

as well as with the layout on your weblog.

Is this a paіd theme or Ԁid үou modify it yourself?

Anyway keep սp the excellent quality writing, it’s

rɑre to see a nice Ƅlߋg like this one today.

I’d like to thank you for the efforts you have put in penning this website. I’m hoping to view the same high-grade blog posts by you in the future as well. In fact, your creative writing abilities has encouraged me to get my own blog now 😉

P.S. Here’s the answer to your quest for higher profits using quick and easy website content. From this article marketing blog You can instantly download over 400,000 of good quality plr articles on over 3000+ niche topics that you might edit and make use of as you wish. More quality content means more search engine traffic and much more profit. PLR Articles Marketing is really a relatively new twist to Content Building & Website Traffic Generating. All the best – Doretha Beltz

I came to your page and noticed you could have a lot more hits. I have found that the key to running a website is making sure the visitors you are getting are interested in your subject matter. There is a company that you can get visitors from and they let you try their service for free. I managed to get over 300 targeted visitors to day to my site. Check it out here: http://posco.com.br/yourls/tny

Hеllo, i read your blog from time to time and i own a similar one and i was

just curіous iff you get a lot of spam comments? If so how do

you reducе it, any plugin or anything you can suggest?

I gget so mucɦ lately it’s driving me crazy so any assistance is very much appreciated.

Howdy! I could have sworn I’ve visited this web site before but after going through a few of the posts I realized it’s new to me. Nonetheless, I’m definitely delighted I came across it and I’ll be bookmarking it and checking back regularly!

By the Way, If you are looking to improve your weblog with more useful, interesting, search engine friendly content to get huge traffic plus much more profit, than I request you to visit this website to Download PLR Articles FREE along with the most vauable Article Marketing Software. Best wishes – Billie

Hey there, I am so glad I found your web site. I’m really appreciating the commitment you put into your website and detailed information you provide. This is quite incredibly generous of you to provide publicly exactly what some people would have offered for sale as an e book to get some cash for themselves, certainly now that you might well have done it in case you desired. Please let me know if you’re looking for a writer for your site. You have some really good articles and I think I would be a good asset. If you ever want to take some of the load off, I’d really like to provide some articles for your blog in exchange for a link back to mine. Please send me an e-mail if interested. Many thanks!

You need targeted visitors for your website so why not get some for free? There is a VERY POWERFUL and POPULAR company out there who now lets you try their website traffic service for 7 days free of charge. I am so glad they opened their traffic system back up to the public! Check it out here: http://axr.be/17r1

Having read this I thought it was very enlightening. I appreciate you finding the time and effort to put this information together. I once again find myself spending a significant amount of time both reading and leaving comments. But so what, it was still worthwhile!