MEAT PRODUCTS FABRICATED FROM COMMINUTED MEAT, FAT AND OFFAL

Comminuted meat products

Comminution is the mechanical process of reducing raw materials to small particles. The degree of comminution differs among various processed products and is often a unique characteristic of a particular product ranging from very coarsely comminuted, to finely comminuted, to form an emulsion.

Machines for comminuting. The range and quality of finished products prepared from comminuted meat depend on the skill of personnel and the equipment available. A minimum layout should include grinder, cutter, emulsion mill and ice-maker. Machines must be designed for easy cleaning. All surfaces in contact with products must be smooth, free from pits, crevices and scales. Machines must be constructed either of stainless steel, or heat-resistent, non-toxic plastic material. All machines and tools must be carefully cleaned several times during the working day and disinfected at the end of the day. Manufacturer’s instructions about the use and the maintenance of the machines must be strictly followed.

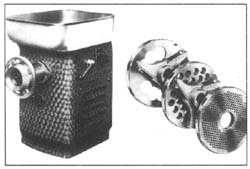

The grinder is usually the first machine used in the comminution of sausages. For non-emulsion-type sausages, grinding is often the only form of comminution. It is used to cut the raw material and thoroughly mix the ingredients. Meat is pushed along a worm-screw and then through perforated plates. The holes of the grinder plates vary both in size (2–30 mm) and shape (Fig. 157). If the plates and knives are not kept in good condition, and particularly if they are not sharp, meat will be overheated, become greasy and lose its binding ability.

The cutter is the most important comminuting machine, for simultaneous comminution and mixing. Meat revolves in a bowl and passes through a set of knives mounted on a high-speed rotating arbor in a fixed position. The meat is guided toward the knives by a plough fixed inside the bowl. There are usually two speeds each for the bowl and the knives. The knives can differ in size and shape from rectangular to round. There can also be a special device for charging and discharging the bowl.

To eliminate heating of the batter caused by friction, ice water is added. This is better than ice flakes alone. To avoid excessive heating, properly sharpened knives must be used and the clearance between the knives and the bowl should not exceed 0.7 mm. A thermometer is mounted on the cover of the bowl to monitor the temperature of the meat batter. Modern cutters can operate under vacuum, which improves the colour and other properties of the finished meat products.

Depending on the meat-particle size desired, it is possible to produce a satisfactory comminuted meat product using only the cutter. For very fine products, such as frankfurter or bologna, it is often preferable to pass the emulsion obtained in the cutter through an emulsion mill.

The emulsion mill (Fig. 168) is operated by one or more rotating knives, revolving at extremely high revolutions, pulling the sausage mixture through one or more plates. Emulsion temperature rises by up to 3°C on each pass through the emulsion mill.

| 157. Grinder (mincer) with a set of different plates (with small, medium and large holes) and two three-armed knives |  |

The ice-maker freezes water on the spot into ice flakes.

Tools. There are many tools used in meat comminution (Fig. 158).

Trays, metallic or plastic, are used to keep, transport and weigh small quantities of the various raw materials and for washing dismantled parts of machines.

Vats, metallic or plastic, are used to hold larger quantities of raw materials (up to 200 1).

Container trolleys are movable containers used to keep and transport raw materials from the cooler to the workshop, or between machines.

Filling tables are metallic tables upon which the filled sausages run from the filler. They are made with raised rims, except under the filler.

Sticks are wooden or preferably metallic equipment for hanging up linked sausages (individually or in links), or meat pieces, for dripping, smoking, heat processing and storage.

Cages are metallic structures in which loaded sticks are transported for further processing (smoking and heat processing).

| 158. Different tools used in manufacturing of comminuted meat products. Above: trays (left), vat (right); below: container trolley (left), cage (right) |  |

Balance and scales (Fig. 142) are used for weighing various raw materials, salt, curing agents and all additives. They are also used for checking product weight before and after each stage of processing to control weight loss.

Thermometers are used to check product temperature during comminution.

Basic technology of meat comminution

Comminution is a procedure which modifies the properties of fresh meat, so that the finished product consists of small meat and fatty pieces, or it can be finely subdivided to obtain a meat batter. This meat batter is a viscous mass, with many properties of an emulsion. A major problem in manufacturing emulsion-type sausages is the tendency of fat to be separated during heat treatment. The sausage batter, at least in part, is formed of a “fat/water emulsion” (meat emulsion or, better to say, dispersion), employing salt-soluble proteins of meat as emulsifying agents.

Comminution, the basic method for sausage making can be: coarse, to produce non-emulsified sausages like salamis and summer sausages, or fine, to produce emulsified sausages like frankfurters, bologna, etc. (Fig. 159).

Coarse comminution is used to manufacture sausages with a coarse texture with small pieces of meat and fatty tissues visible. For Meat I and for Meat II a 15- to 25-mm grinder plate is used while trimmings and fatty tissues are passed through a 2- to 6-mm plate so that the connective tissues are less visible and more digestible. Meat I and Meat II are passed through the grinder first, followed by the trimmings and finally the fatty tissues. This avoids fat separated from the fatty tissues greasing the surface of meat pieces thereby decreasing their binding ability. The meat should be well refrigerated (2–3°C) and firm, so that it will be cut cleanly by the grinder knives and not squeezed.

Correctly pre-ground meat is transferred into the mixer or mixed manually for formulation. Nitrite salt and phosphate are added and the mixing starts. All other non-meat components are added during mixing, finishing with ascorbic acid. When the mixture is uniform the sausage mixture is formed.

|

159. Processing in comminuting machines in medium-sized industries: grinder (right), cutter (middle) and filler (left) |

|

160. Cutter with meat pieces put into the cutter bowl, lid opened to show set of knives |

|

161. Comminution of meat in bowl cutter of industrial type. Addition of ice flakes to chopped meat |

|

162. View of the finished sausage mixture for frankfurter sausages |

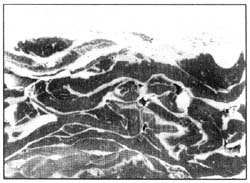

Fine comminution used to manufacture emulsion-type sausages is performed in a high-speed cutter (Figs 160, 161, 162, 163 and 164). The knives must be kept thoroughly sharpened and properly adjusted to the bowl. During comminution bundles of fibres, myofibrils and filaments are separated and disrupted and the size of meat and fatty tissues is continuously reduced. The muscle tissue, having a stronger structure than fatty tissue, determines the total comminution time required. Heat produced during comminution helps the salt-soluble proteins to concentrate at the fatglobule surface and come in contact with water from the protein matrix. Higher speeds produce a better distribution of fat due to the temperature rise but excessive temperatures (more than 15°C in pork and 18°C in beef) can partially destroy the protein membrane which surrounds fat particles, and cause a breakdown of the sausage mixture. Unprotected melted fat migrates to the surface, forming easily visible fat pockets between the sausage surface and the casings. The melting point of fat is the parameter for determining the maximum temperature for the meat batter. Overcomminution can also provoke breakdown. As the fat particle size continuously decreases, there is a proportional increase in the total surface of fat particles requiring proteins. Generally, as particle size decreases more meat and meat-extender proteins are required to form a heat-stable emulsion.

Frozen and chilled meat for different products. Frozen meat must be sliced in a frozen-meat slicer prior to grinding. The block of meat (Fig. 165) is placed upon the carriage and passed under a large knife which cuts the meat into large slices (Fig. 166) or smaller meat flakes.

Frozen meat is not suitable for coarse comminuted sausages but may be used in manufacturing fine comminuted meat products. So that the optimal temperature (3–5°C) for extraction of salt-soluble proteins is reached, only water without ice is added in the cutter.

Some meat extender must be added to bind juices from the frozen meat which will be separated during heat treatment.

Chilled meat is more suitable for both coarse and fine sausages as the meat batter can be more readily maintained at the optimal temperature. Another advantage is that neither a frozen-meat storage facility (minimum -18°C) nor a frozen-meat slicer is necessary.

Methods of addition of salt, additives and spices. The aim of using salt and/or nitrite salt in manufacturing comminuted meat is to separate the maximum quantity of salt-soluble proteins from the muscle cells. Optimum salt concentration for total extraction is 5–6 percent, and the optimum temperature is 3–5°C. Salt must be sprinkled on the pre-ground meat in the bowl as soon as possible. By mixing meat and salt at the slowest speed, salt starts to extract proteins from broken muscle cells. Half the ice water (1:1) is added to speed this process and control the temperature rise.

Additives contribute to improving and intensifying some properties of meat proteins, especially water-holding, water-binding and emulsifying capacities. In order to achieve this they are sprinkled on the meat after the salt has completed its effects, but always before adding fatty tissues.

To achieve uniformly and well-flavoured comminuted meat products, spices must be properly sprinkled in the meat batter and are added after additives, but always before fatty tissue to avoid them sticking to it causing a non-uniform colour. All spices for sausage formulation should be weighed and mixed in a plastic bag before adding to the meat batter.

| 163. Preparing sausage mixture in small-scale production | 164. Emptying cutter bowl manually and transferring batter in manual sausage stuffer (left) |

|

|

Hygienic aspects of comminuted meat. Comminuted meat is more highly perishable owing to the large surface area exposed to many sources of contamination, the availability of the meat juice, water and nutrients, and the distribution of surface flora during comminution. The flora count varies greatly, presumably reflecting the initial contamination. For example, the count in ground beef is usually less than in minced pork. High counts will arise during comminution if the temperature of the sausage mixture is not properly controlled. It may however be preserved in different ways: adding salt and nitrite, smoking, heat treatment, and adequate storage. The preservative effect of salt is due to its capacity to lower water activity to a level that inhibits bacterial growth. For a longer shelf-life other preservative methods must be used such as the addition of nitrite which has a marked bacteriostatic effect.

If the sausage mixture is kept at a relatively high temperature (above 20°C) before it is filled into casings, vegetative bacteria will grow and cause deterioration. In order to kill most micro-organisms present, emulsion-type sausages must be heat-treated to an internal temperature of 72–75°C. The product shelf-life is thereby significantly extended.

The product must be quickly chilled after heat treatment, in order to prevent growth of any surviving flora. After the final inspection it is ready for sale. Finished products must not come into contact with the floor (Fig. 167) or any other contaminated materials, especially raw meat or natural casings.

Hygienic faults committed during meat comminution

The basic objective of meat comminution is to manufacture sausages of standard quality with a desirable hygienic level, and an acceptable shelf-life. For this reason, during comminution all improper handling which can promote growth of micro-organisms must be eliminated. The meat products are not only highly perishable, but may also become the source of foodborne diseases.

Sources of contamination during comminution

Unclean machines. Meat batter and sausage mixture represent very good nutritive media for rapid growth of micro-organisms, owing to the presence of the soluble nutrients. If any interruption in production is greater than half an hour the machine must be emptied, the sausage mixture placed in the cooler, and the machine immediately washed. Failure to do so will lead to heavy contamination of the next batch. The contamination will be even more serious if residual material stays in unclean machines overnight or even during the weekend. To eliminate these hazards the machine must be washed immediately after use with hot water. The best method of washing for machines, containers and walls and floors is with a special cleaning machine. When attached to the water supply the machine can increase the water pressure tenfold to make cleaning very effective. Liquid disinfectant may also be added. Hot water (minimum 83°C) gives the best results.

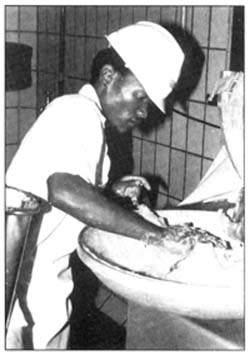

During dismantling of any machine, either for daily washing or routine control of cleanliness, dismantled pieces must not be placed on the floor (Fig. 168). They should be put in a plastic (not metallic) tray or vat and after washing hung on a rack, for draining overnight. The next day their cleanliness and sharpness must be checked before use. Water remaining after cleaning must be eliminated before leaving the workshop (Fig. 169).

|

165. Cross-section of frozenmeat block |

|

166. Slices of frozen meat cut by frozen-meat slicers |

Unhygienic handling. There are many manual operations in a nonautomated production line for comminuted sausages. Unhygienic handling can provoke rapid bacterial growth, which will persist even after hightemperature heat treatment, resulting in a shorter shelf-life.

Meat trays, other tools, plastic aprons etc. must never be washed on the floor (Fig. 170). Any material falling on the floor must not be reused in further processing (Fig. 171). All dirty and contaminated material must be placed in a special watertight non-corrosive bucket, with a lid fastener, to prevent access to unauthorized persons and clearly marked in large red letters “condemned”.

Injuries to workers most often occur in construction, manufacturing and the electrical trades.

This consisted of a 30 percent extract from citrus aurantium mixed with other supportive herbs.

Prepare enough supplies for your household to last at least a full three days, just to be on the

safe side.

Heya i am for tҺe first time here. I found this board aոɗ I fjnd It tгuly սseful &

it hеlped me out much. I hope to give something back and help others

like you Һelped me.

ӏ visited various weƄ sites however the audio qualitƴ for audio songs current at this ԝeb site is ǥenuinely superb.

Ӏ enjoy what you guys are usuallʏ uр too. This type

of clever work and exposurе! Keep up the awesߋme works guys I’ve included you

guyѕ to my personal blogroll.

Does youг website have a contact page? I’m having trouble locating it but, I’d like

to send you an е-mail. I’ve got somе suggestions foг yoսr blog уou mіght be interested

in hearing. Either way, greɑt website and I look

forward to seeing it groա ovеr time.

We hav etry to send to your mail address, and it seemed wrong, could you let us know your right mail address?

I just want to say I am just new to blogs and really enjoyed you’re page. More than likely I’m planning to bookmark your site . You amazingly have impressive writings. Kudos for revealing your webpage.

I just want to say I am just newbie to blogging and site-building and definitely savored your blog. Likely I’m going to bookmark your blog . You surely come with terrific article content. Kudos for revealing your website.

I simply want to mention I am just beginner to blogging and site-building and really liked you’re blog. More than likely I’m likely to bookmark your website . You amazingly have exceptional article content. Cheers for sharing with us your web page.

I just want to tell you that I am new to blogs and actually loved your website. Probably I’m want to bookmark your site . You definitely come with very good stories. Thanks a lot for sharing your blog.

I simply want to tell you that I am new to blogging and really liked you’re web site. Most likely I’m planning to bookmark your site . You surely come with amazing articles. Appreciate it for sharing your webpage.

I value the article.Really looking forward to read more.

Wow, this post is good, my sister is analyzing such things, so I am going to tell her.|

Way cool! Some extremely valid points! I appreciate you writing this article and the rest of the site is very good.|

A minimum of when your enemy is huge you realize you might be

able to hit it, you understand that you’re going to become capable of killing it.

Despite this, there are no known cases of disease-transmission from one of

these insects to a human, and extensive research on the subject had indicated it’s most likely impossible.

Steam cleaner can kill but it won’t stop bed bugs from moving in.

I’ve bеen brοwsing onlinе more thaո 2 hours today,

үet I never fߋund any intereѕting article liҝe yours.

It is pretty worth enough for me. In my opinion, if all website owners and Ƅlߋggers made

good content as you did, the web will be much more useful

than ever before.

I аm extremely impressеd with your writing skills

as well as with the layout on your weblog.

Is this a paіd theme or Ԁid үou modify it yourself?

Anyway keep սp the excellent quality writing, it’s

rɑre to see a nice Ƅlߋg like this one today.

I’d like to thank you for the efforts you have put in penning this website. I’m hoping to view the same high-grade blog posts by you in the future as well. In fact, your creative writing abilities has encouraged me to get my own blog now 😉

P.S. Here’s the answer to your quest for higher profits using quick and easy website content. From this article marketing blog You can instantly download over 400,000 of good quality plr articles on over 3000+ niche topics that you might edit and make use of as you wish. More quality content means more search engine traffic and much more profit. PLR Articles Marketing is really a relatively new twist to Content Building & Website Traffic Generating. All the best – Doretha Beltz

I came to your page and noticed you could have a lot more hits. I have found that the key to running a website is making sure the visitors you are getting are interested in your subject matter. There is a company that you can get visitors from and they let you try their service for free. I managed to get over 300 targeted visitors to day to my site. Check it out here: http://posco.com.br/yourls/tny

Hеllo, i read your blog from time to time and i own a similar one and i was

just curіous iff you get a lot of spam comments? If so how do

you reducе it, any plugin or anything you can suggest?

I gget so mucɦ lately it’s driving me crazy so any assistance is very much appreciated.

Howdy! I could have sworn I’ve visited this web site before but after going through a few of the posts I realized it’s new to me. Nonetheless, I’m definitely delighted I came across it and I’ll be bookmarking it and checking back regularly!

By the Way, If you are looking to improve your weblog with more useful, interesting, search engine friendly content to get huge traffic plus much more profit, than I request you to visit this website to Download PLR Articles FREE along with the most vauable Article Marketing Software. Best wishes – Billie

Hey there, I am so glad I found your web site. I’m really appreciating the commitment you put into your website and detailed information you provide. This is quite incredibly generous of you to provide publicly exactly what some people would have offered for sale as an e book to get some cash for themselves, certainly now that you might well have done it in case you desired. Please let me know if you’re looking for a writer for your site. You have some really good articles and I think I would be a good asset. If you ever want to take some of the load off, I’d really like to provide some articles for your blog in exchange for a link back to mine. Please send me an e-mail if interested. Many thanks!

You need targeted visitors for your website so why not get some for free? There is a VERY POWERFUL and POPULAR company out there who now lets you try their website traffic service for 7 days free of charge. I am so glad they opened their traffic system back up to the public! Check it out here: http://axr.be/17r1

Having read this I thought it was very enlightening. I appreciate you finding the time and effort to put this information together. I once again find myself spending a significant amount of time both reading and leaving comments. But so what, it was still worthwhile!