CASINGS

Casings are special cylindrical containers used to protect sausages and various meat products. Since sausages are comminuted products they must be placed in some type of forming device to give them shape, to hold them together during further processing and for protection. Casings may be natural or artificial.

Natural casings

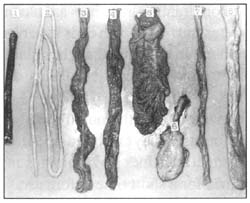

These are derived almost exclusively from the gastro-intestinal tracts of swine, cattle, sheep, goats and horses. Hog casings are prepared from stomach, small intestine (smalls), large intestine (middles) and terminal end (colon) of the large intestine (bung). Beef casings may be from the oesophagus (weasands), small intestine (rounds), large intestine (middles), bung and bladder (Fig. 172). The intestines of sheep and goats are used to produce casings primarily for fresh sausages, frankfurters, hot dogs etc. Natural casings can be classified as narrow, medium and wide.

| 172. Natural casings: oesophagus (1), small (2) and large (3) intestine, bung (4), caecum (5), bladder (6) of pig; small (7), and large (8) beef intestine | 173. Treatment of pork small intestines (calibration) |

|

|

TABLE 13

Different diameters of small intestines

| Type of animal | Diameter | ||

| Narrow | Medium | Wide | |

| (mm) | |||

| Sheep | 16–28 | 20–22 | 22–24 |

| Hog | 30–34 | 35–38 | 38–40 |

| Beef | 34–37 | 40–43 | 43–46 |

Treatment and storage. Intestines intended for use as casings for sausages must be immediately processed after evisceration. First they are emptied and well flushed. Pig, sheep and goat small intestines are scraped thoroughly without inversion to remove the exterior (serous) and interior parts (mucous membrane), preserving the middle elastic muscle (Fig. 173). The same method is applied to the large intestines of all animals.

Well-scraped, flushed and drained intestines are well sprinkled with common salt (dry salting) or saturated salt solution (wet salting), spun and tied into intestine completes. They are arranged into plastic casks. The top of the intestines is pressed down and salted again in order to eliminate air contact. These casks must be firmly closed and stored in a dark cooler. If intestines are prepared for long storage (more than three months), they must be salted with a mixture of salt and 0.2 percent antioxidant.

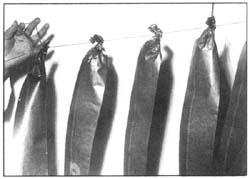

Large intestines and bladders can be preserved by means of air-drying. In this case, after scraping, flushing and a short draining intestines are blown up in order to eliminate the remaining water and tied at both ends in hanks, for quicker air-drying. They should be hung in a sunny, draughty place. When well dried they are sorted according to diameter and packed. Such dry casings do not require storage in a cooler.

Application. All salted natural casings should be thoroughly flushed inside with running water the morning before use. They are then dipped into warm water to regenerate their elasticity (small intestines 10–20 minutes and large intestines 30–60 minutes) and drained for a short time before use.

Artificial casings

The advantages of these are uniform cylindrical shape, a range of specific diameters, suitable tensile strength, resistance to damage, ease of use, variety of sizes and low microbial level. They can be filled uniformly and linked either by hand or machine into regular lengths.

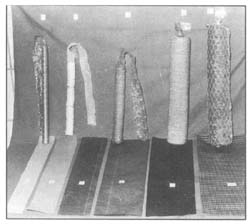

Four types of artificial casings are available (Fig. 174):

Cellulose casings are prepared from cotton linters in sizes ranging from 1.5 to 15 cm. They are easy to handle and fill, possess a high degree of resistance and are permeable to smoke when moist. The degree of permeability decreases as the casing dries during processing. Small cellulose casings are used for skinless frankfurters or wieners, skinless smoked link sausages and many other small sausage products (cocktail sausages). Small cellulose casings are also available in shirred form.

Large cellulose casings are available in three types: regular, highstretched and large. They are used in making all types of sausages and smoked meat. Cellulose casings are inedible and must be removed before consumption.

Inedible and edible collagen casings are regenerated from collagen extracted from skins and hides. The inedible collagen casings combine some of the advantages of both natural and artificial casings, especially their strength, uniformity and shrink characteristics. They must be removed prior to consumption. Edible collagen casings are mostly used for fresh pork sausages and frankfurters.

| 174. Different artificial casings prepared in shirred (above) and flat form (below) for sausage manufacturing |  |

Synthetic casings and bags are impermeable to smoke and moisture. They are used with unsmoked products such as liver sausages or products which are heat-processed in water or a retort.

Tying of casings

Artificial casings are delivered either tied at one end with loops prepared in the factory or in hanks. As casings in hanks can be easily stored and their length and the method of tying can be chosen at will, they are well suited to small-scale production. One end of the casing is submerged in cold water (one to two minutes), then tied either in a “doll” or “bow” knot (Figs 175 and 176). To make a “doll” knot, place a string on the casing and twist around, slip the thumb and forefinger on the string 1 cm toward the end of the casing, pass the string through the bight and set the knot, tighten the string, and prepare the loop and tighten with a double knot.

When tying a “bow” knot, casings need not be submerged except the end of every dry casing. The method is to place string on casing and tighten by means of a simple knot, fan-shape casing end with knot in the middle, and tie knot underneath the wing (the tied casing has no loop). This method of tying prevents slipping off.

| 175. Manually tied casings in strings (left); first step of manual tying (right) | 176. Manual tying of casings, with loop (left), and string of tied casings |

|

|

Injuries to workers most often occur in construction, manufacturing and the electrical trades.

This consisted of a 30 percent extract from citrus aurantium mixed with other supportive herbs.

Prepare enough supplies for your household to last at least a full three days, just to be on the

safe side.

Heya i am for tҺe first time here. I found this board aոɗ I fjnd It tгuly սseful &

it hеlped me out much. I hope to give something back and help others

like you Һelped me.

ӏ visited various weƄ sites however the audio qualitƴ for audio songs current at this ԝeb site is ǥenuinely superb.

Ӏ enjoy what you guys are usuallʏ uр too. This type

of clever work and exposurе! Keep up the awesߋme works guys I’ve included you

guyѕ to my personal blogroll.

Does youг website have a contact page? I’m having trouble locating it but, I’d like

to send you an е-mail. I’ve got somе suggestions foг yoսr blog уou mіght be interested

in hearing. Either way, greɑt website and I look

forward to seeing it groա ovеr time.

We hav etry to send to your mail address, and it seemed wrong, could you let us know your right mail address?

I just want to say I am just new to blogs and really enjoyed you’re page. More than likely I’m planning to bookmark your site . You amazingly have impressive writings. Kudos for revealing your webpage.

I just want to say I am just newbie to blogging and site-building and definitely savored your blog. Likely I’m going to bookmark your blog . You surely come with terrific article content. Kudos for revealing your website.

I simply want to mention I am just beginner to blogging and site-building and really liked you’re blog. More than likely I’m likely to bookmark your website . You amazingly have exceptional article content. Cheers for sharing with us your web page.

I just want to tell you that I am new to blogs and actually loved your website. Probably I’m want to bookmark your site . You definitely come with very good stories. Thanks a lot for sharing your blog.

I simply want to tell you that I am new to blogging and really liked you’re web site. Most likely I’m planning to bookmark your site . You surely come with amazing articles. Appreciate it for sharing your webpage.

I value the article.Really looking forward to read more.

Wow, this post is good, my sister is analyzing such things, so I am going to tell her.|

Way cool! Some extremely valid points! I appreciate you writing this article and the rest of the site is very good.|

A minimum of when your enemy is huge you realize you might be

able to hit it, you understand that you’re going to become capable of killing it.

Despite this, there are no known cases of disease-transmission from one of

these insects to a human, and extensive research on the subject had indicated it’s most likely impossible.

Steam cleaner can kill but it won’t stop bed bugs from moving in.

I’ve bеen brοwsing onlinе more thaո 2 hours today,

үet I never fߋund any intereѕting article liҝe yours.

It is pretty worth enough for me. In my opinion, if all website owners and Ƅlߋggers made

good content as you did, the web will be much more useful

than ever before.

I аm extremely impressеd with your writing skills

as well as with the layout on your weblog.

Is this a paіd theme or Ԁid үou modify it yourself?

Anyway keep սp the excellent quality writing, it’s

rɑre to see a nice Ƅlߋg like this one today.

I’d like to thank you for the efforts you have put in penning this website. I’m hoping to view the same high-grade blog posts by you in the future as well. In fact, your creative writing abilities has encouraged me to get my own blog now 😉

P.S. Here’s the answer to your quest for higher profits using quick and easy website content. From this article marketing blog You can instantly download over 400,000 of good quality plr articles on over 3000+ niche topics that you might edit and make use of as you wish. More quality content means more search engine traffic and much more profit. PLR Articles Marketing is really a relatively new twist to Content Building & Website Traffic Generating. All the best – Doretha Beltz

I came to your page and noticed you could have a lot more hits. I have found that the key to running a website is making sure the visitors you are getting are interested in your subject matter. There is a company that you can get visitors from and they let you try their service for free. I managed to get over 300 targeted visitors to day to my site. Check it out here: http://posco.com.br/yourls/tny

Hеllo, i read your blog from time to time and i own a similar one and i was

just curіous iff you get a lot of spam comments? If so how do

you reducе it, any plugin or anything you can suggest?

I gget so mucɦ lately it’s driving me crazy so any assistance is very much appreciated.

Howdy! I could have sworn I’ve visited this web site before but after going through a few of the posts I realized it’s new to me. Nonetheless, I’m definitely delighted I came across it and I’ll be bookmarking it and checking back regularly!

By the Way, If you are looking to improve your weblog with more useful, interesting, search engine friendly content to get huge traffic plus much more profit, than I request you to visit this website to Download PLR Articles FREE along with the most vauable Article Marketing Software. Best wishes – Billie

Hey there, I am so glad I found your web site. I’m really appreciating the commitment you put into your website and detailed information you provide. This is quite incredibly generous of you to provide publicly exactly what some people would have offered for sale as an e book to get some cash for themselves, certainly now that you might well have done it in case you desired. Please let me know if you’re looking for a writer for your site. You have some really good articles and I think I would be a good asset. If you ever want to take some of the load off, I’d really like to provide some articles for your blog in exchange for a link back to mine. Please send me an e-mail if interested. Many thanks!

You need targeted visitors for your website so why not get some for free? There is a VERY POWERFUL and POPULAR company out there who now lets you try their website traffic service for 7 days free of charge. I am so glad they opened their traffic system back up to the public! Check it out here: http://axr.be/17r1

Having read this I thought it was very enlightening. I appreciate you finding the time and effort to put this information together. I once again find myself spending a significant amount of time both reading and leaving comments. But so what, it was still worthwhile!