PERSONNEL HYGIENE

Probably as important as anything in the production of clean, wholesome, unspoiled products is the attitude of the workers toward cleanliness. Personnel with clean hands, clothing and good hygienic practices are absolutely essential to the production of high-quality foods.

All clothing should be clean, in good repair and made of washable material. Street clothing should be covered with coats or gowns while handling exposed product. White or light-coloured clothing is most desirable and garments that become soiled or contaminated should be changed when necessary.

All persons working with exposed meat products should have their hair under control, either completely covered with a clean cap or hat or confined by a hairnet to prevent hair from falling into products.

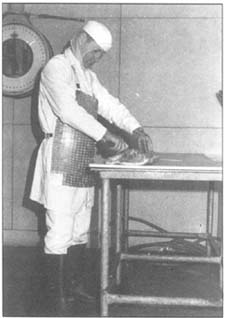

Safety devices such as aprons, wrist guards and mesh gloves must be made of impervious material, clean and in good repair. At no time should leather aprons, wrist guards or other devices be worn unless clean, washable coverings are used over them. Light-coloured rubber or plastic gloves may be worn by product handlers only if clean and in good repair (Fig. 3).

No person working with meats should wear any kind of jewellery, badges or buttons that may come loose and be accidently included in the product.

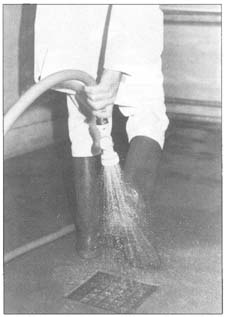

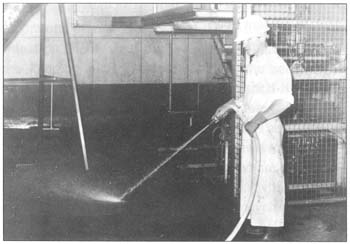

Shoes and boots should be worn at all times and should be appropriate for the operations being conducted. They should also be made of impervious materials (Fig. 4). Any aprons, knives and footwear that become contaminated during operations should be routinely cleaned in areas or facilities provided for that purpose.

No cloth twine, belts or other similar materials should be used to cover implement handles or used in other places where they may harbour filth and serve as a ready source of product contamination.

| 3. Workers must wear clean and protective clothing. Note the hairnet to prevent contamination from loose hairs and the chain-mail apron and glove to protect from knife cuts | 4. Footwear should be waterproof so that it can be washed frequently, and always when moving to another part of the factory |

|

|

All unsanitary practices should be avoided by meat handlers. No one should smoke or use tobacco in areas where edible products and ingredients are handled, prepared or stored, or where equipment and utensils are cleaned. When handling edible products, scratching the head, placing fingers in or around the nose or mouth, sneezing or coughing on the product should never occur. Workers must also guard against contaminating products from localized infections or sores.

Workers can contaminate carcasses and meat through handling, coughing and sneezing. This may cause rapid spoilage of the meat or, more seriously, food poisoning. Coughs and sneezes are a particularly effective way of transmitting bacteria to meat. Transfer of faecal matter either of animal or human origin to the meat is particularly hazardous. Most contamination on the hands of workers in slaughter floors with faecal matter comes from the hides and fleeces.

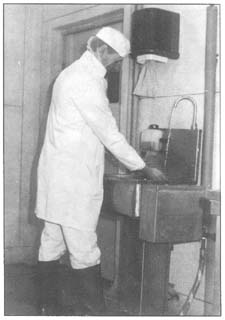

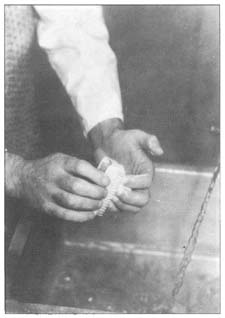

| 5. Hands should be frequently washed under running hot water and always after visiting the toilet, smoking, coughing or sneezing, handling money, garbage, soiled or infected material | 6. Particular attention should be paid to cleaning under the fingernails with a brush |

|

|

Hands should be washed frequently to remove all visible soiling. Stainless-steel sinks without plugs should be conveniently accessible to all workers. Water should be supplied at approximately 43°C to a simple tap which is foot- or knee-operated. Liquid disinfectant soap and paper towels should be available (Fig. 5). Particular attention should be paid to cleaning under the fingernails (Fig. 6). Hands should also be thoroughly washed after using the toilet, smoking, coughing or sneezing, handling money, garbage or soiled or infected material.

| 7. The cleaning operation begins with clearing all debris from the floor |  |

| 8. All surfaces must be thoroughly washed down at the end of each day |  |

All precautions should be taken to prevent product contamination by visitors or other persons who are simply passing through the work area.

ROUTINE CLEANING OF ROOMS AND EQUIPMENT

The floors should be kept clear of all debris (Fig. 7), such as hooves and horns, in slaughterhalls or other inedible parts or fat and meat particles in cutting, processing and by-product handling areas, and must be frequently washed down. At the end of each day a thorough cleaning programme should be followed (Fig. 8). All matter should be removed from floors, platforms, gullies, etc., followed by a thorough hosing down of walls, floors and all surfaces to loosen dirt. Finally a strong cleaning solution should be applied and left for a while before being rinsed off. A thorough inspection should be made afterwards and any areas remaining soiled should be cleaned again.

In order to maintain the cleanest possible products a standard cleaning routine of the equipment should be established. Initially all large pieces of refuse material should be scraped or swept together and disposed of. Follow-up should include scrubbing of the equipment using brushes and a soap or detergent and a complete sanitizing with hot water at 82°C and an approved chlorine or iodine rinse. Finally, a coating of light mineral oil can be applied to metal equipment, particularly that not fabricated of stainless steel, to prevent rust.

http://www.fao.org/docrep/004/T0279E/T0279E02.htm

Hey! I know this is kinda off topic nevertheless

I’d figured I’d ask. Would you be interested in exchanging links or maybe guest authoring a blog post or vice-versa?

My website covers a lot of the same topics as yours and I believe we could greatly benefit from

each other. If you’re interested feel free

to shoot me an email. I look forward to hearing from you!

Terrific blog by the way!

cheap audemars piguet watches replica

I’m really impressed with your writing skills as well as with the

layout on your blog. Is this a paid theme or did you customize it yourself?

Either way keep up the nice quality writing, it is rare to see a great blog like this one today.

Thanks, It’s just the wordpress template: Twenty Twelve