EVISCERATION

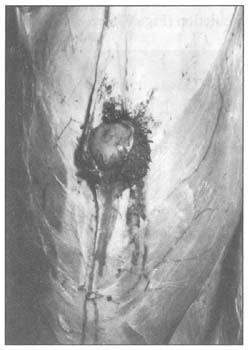

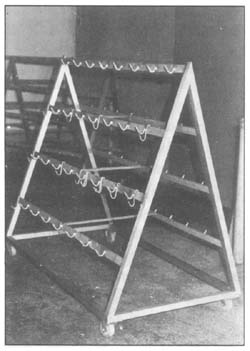

With all species care must be taken in all operations not to puncture the viscera (Fig. 42). All viscera must be identified with the carcass until the veterinary inspection has been passed. After inspection the viscera should be chilled on racks etc. for better air circulation (Fig. 43).

Cattle

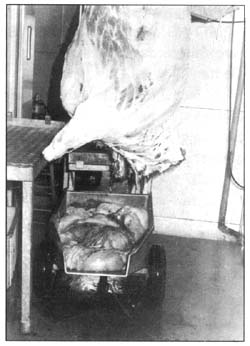

The brisket is sawn down the middle (Fig. 44). In the combined horizontal/ vertical system this is done with the animal resting on the cradle. The carcass is then raised to the half-hoist position and when hide removal is complete the abdominal cavity is cut carefully along the middle line. The carcass is then fully hoisted to hang clear of the floor so that the viscera fall out under their own weight (Fig. 45). They are separated into thoracic viscera, paunch and intestines for inspection and cleaning (Figs 46 and 47). If any of the stomachs or intestines are to be saved for human consumption, ties are made at the oesophagus/stomach, stomach/duodenum boundaries, the oesophagus and rectum having been tied off during hide removal. This prevents cross-contamination between the paunch and the intestines.

Small ruminants

A small cut is made in the abdominal cavity wall just above the brisket, and the fingers of the other hand are inserted to lift the body wall away from the viscera as the cut is continued to within about 5 cm of the cod fat or udder.

The omentum is withdrawn, the rectum (tied off) loosened, and the viscera freed and taken out. The food-pipe (tied off) is pulled up through the diaphragm. The breastbone is split down the middle taking care not to puncture the thoracic organs which are then removed.

Pigs

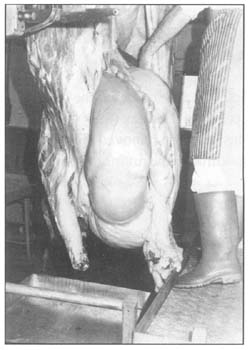

Loosen and tie off the rectum. Cut along the middle line through the skin and body wall from the crotch to the neck (Fig. 48). Cut through the pelvis and remove the bladder and sexual organs. In males the foreskin must not be punctured as the contents are a serious source of contamination. All these organs are considered inedible.

| 42. When cutting through the abdomen wall, if the viscera are punctured their contents will severely contaminate the carcass | 43. A portable rack suitable for hanging offal for chilling |

|

|

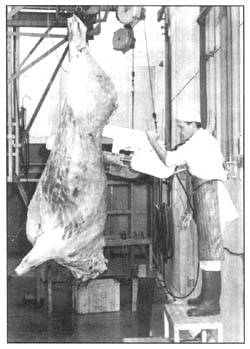

| 44. A mechanical saw speeds the splitting of the brisket but care must be taken not to puncture the viscera |  |

| 45. After carefully cutting the abdominal wall along the midline the viscera fall out under their own weight | 46. A suitable receptacle should catch the viscera so that they are not contaminated by contact with the floor |

|

|

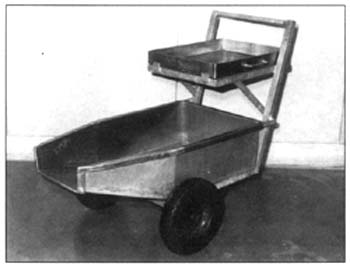

| 47. A portable cart suitable for catching cattle stomachs and intestines with a separate tray for edible offal such as liver, heart and lungs |  |

Remove the abdominal and thoracic viscera intact. Avoid contact with the floor or standing platform.

The kidneys are usually removed after the carcass has been split down the backbone. The head is usually left on until after chilling.

SPLITTING, WASHING AND DRESSING OF CARCASSES

Hygienic carcass splitting with simple equipment

Cattle

Work facing the back of the carcass. Split the carcass down the backbone (chine) with a saw or cleaver from the pelvis to the neck (Figs 49 and 50). Sawing gives a better result but bone dust must be removed (Fig. 51). If a cleaver is used, it may be necessary to saw through the rump and loin in older animals.

The saw and cleaver should be sterilized in hot (82°C) water between carcasses. Power saws increase productivity.

| 48. The body wall is split down the midline taking care not to puncture the viscera |  |

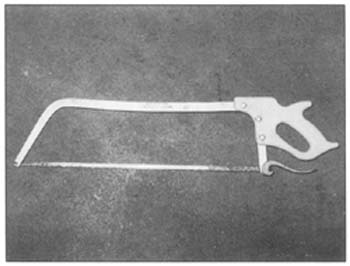

| 49. Mechanical saw for splitting the backbone (chine) of beef carcasses | 51. Carcasses should be spray-washed to remove visible staining, paying particular attention to bone dust and the internal surface, but without using excessive amounts of water |

|

|

| 50. Hand-saws are much slower than mechanical saws though they are preferable to cleavers which splinter bones |  |

Pigs

These are suspended and are split down the backbone as for cattle, but the head is generally left intact (Fig. 94).

Sheep

Sheep and lamb carcasses are generally sold entire. If necessary they can be split by saw or cleaver, but a saw will probably be necessary for older animals.

Carcass washing

The primary object of carcass washing is to remove visible soiling and blood stains and to improve appearance after chilling (Fig. 51). Washing is no substitute for good hygienic practices during slaughter and dressing since it is likely to spread bacteria rather than reduce total numbers. Stains of gut contents must be cut off. Wiping cloths must not be used.

Carcass spraying will remove visible dirt and blood stains. Water must be clean. Soiled carcasses should be sprayed immediately after dressing before the soiling material dries, thus minimizing the time for bacterial growth. Under factory conditions bacteria will double in number every 20 or 30 minutes.

In addition to removing stains from the skinned surface, particular attention should be paid to the internal surface, the sticking wound and the pelvic region.

A wet surface favours bacterial growth so only the minimum amount of water should be used and chilling should start immediately. If the cooler is well designed and operating efficiently the carcass surface will quickly dry out, inhibiting bacterial growth.

Bubbling of the subcutaneous fat is caused by spraying with water at excessively high pressure, which may be due to the pressure in the system or a result of holding the spray nozzle too close to the carcass.

Carcass dressing

The object of carcass dressing is to remove all damaged or contaminated parts and to standardize the presentation of carcasses prior to weighing. Specifications will differ in detail for different authorities. Veterinary inspection of carcasses and offal can only be carried out by qualified personnel. Where signs of disease or damage are found the entire carcass and offal may be condemned and must not enter the food chain, but more often the veterinarian will require that certain parts, for instance those where abscesses are present, be removed and destroyed. Factory personnel must not remove any diseased parts until they have been seen by the inspector otherwise they may mask a general condition which should result in the whole carcass being condemned. Any instructions from the inspector to remove and destroy certain parts must be obeyed.

REFRIGERATION, HANDLING AND TRANSPORT OF CARCASSES AND MEAT

Refrigeration of carcasses

Carcasses should go into the cooler as soon as possible and should be as dry as possible. The object of refrigeration is to retard bacterial growth and extend the shelf-life. Chilling meat post-mortem from 40°C down to 0°C and keeping it cold will give a shelf-life of up to three weeks, provided high standards of hygiene were observed during slaughter and dressing.

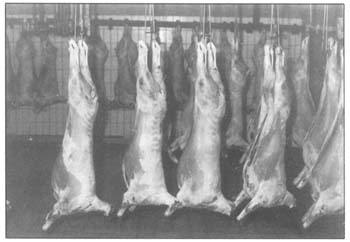

Carcasses must be placed in the cooler immediately after weighing. They must hang on rails and never touch the floor (Fig. 52). After several hours the outside of a carcass will feel cool to the touch, but the important temperature is that deep inside the carcass. This must be measured with a probe thermometer (not glass), and used as a guide to the efficiency of the cooling.

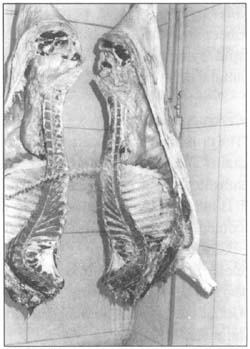

| 52. Sheep carcasses in the chill-room, hung on rails clear of the floor and spaced to allow air circulation to speed drying |  |

The rate of cooling at the deepest point will vary according to many factors including the efficiency of the cooler, the load, carcass size and fatness. As a general guide a deep muscle temperature of 6–7° C should be achieved in 28 to 36 hours for beef, 12 to 16 hours for pigs and 24 to 30 hours for sheep carcasses. Failure to bring down the internal temperature quickly will result in rapid multiplication of bacteria deep in the meat resulting in off-odours and bone-taint.

High air speeds are needed for rapid cooling but these will lead to increased weight losses due to evaporation unless the relative humidity (RH) is also high. However, if the air is near to saturation point (100 percent RH) then condensation will occur on the carcass surface, favouring mould and bacteria growth. A compromise between the two problems seems to be an RH of about 90 percent with an air speed of about 0.5 m/second. Condensation will also occur if warm carcasses are put in a cooler partially filled with cold carcasses.

The cooler should not be overloaded beyond the maximum load specified by the manufacturers and spaces should be left between carcasses for the cold air to circulate. Otherwise cooling will be inefficient and the carcass surface will remain wet, favouring rapid bacterial growth forming slime (see below).

Once filled, a cooler should be closed and the door opened as little as possible to avoid sudden rises in temperature. When emptied, it should be thoroughly washed before refilling. Personnel handling carcasses during loading and unloading operations should follow the strictest rules regarding their personal hygiene and clothing and should handle carcasses as little as possible.

Marketing of meat under refrigeration

Chilled meat must be kept cold until it is sold or cooked. If the cold chain is broken, condensation forms and microbes grow rapidly. The same rules about not overloading, leaving space for air circulation, opening doors as little as possible and observing the highest hygiene standards when handling the meat apply. An ideal storage temperature for fresh meat is just above its freezing point, which is about – 1°C (- 3°C for bacon because of the presence of salt). The expected storage life given by the International Institute of Refrigeration of various types of meat held at these temperatures is as follows:

| Type of meat | Expected storage life at – 1°C |

| Beef | up to 3 weeks (4–5 with strict hygiene) |

| Veal | 1–3 weeks |

| Lamb | 10–15 days |

| Pork | 1–2 weeks |

| Edible offal | 7 days |

| Rabbit | 5 days |

| Bacon | 4 weeks (at – 3°C) |

Under commercial conditions, meat temperatures are rarely kept at – 1°C to 0°C, so actual storage times are less than expected. The times would also be reduced if RH were greater than 90 percent.

Meat should be placed in the refrigerator immediately following receipt. Any parts which show signs of mould growth or bacterial slime should be trimmed off and destroyed. Hands must be thoroughly washed after handling such trimmings and knives must be sterilized in boiling water. The refrigerator should be thoroughly cleaned after finding such meat and should also be cleaned on a regular basis.

Carcasses, quarters and large primals should not be cut into smaller portions before it is necessary as this will expose a greater surface area for bacteria to grow. Freshly cut surfaces are moist and provide a better medium for bacterial growth than the desiccated outer surfaces of cuts that have been stored for some time.

An accurate thermometer should be placed in the refrigerator and checked regularly. The temperature should remain within a narrow range (0° to + 1°C).

Transport of meat

Vehicles for transporting meat and carcasses should be considered as an extension of the refrigerated storage. The object must be to maintain the meat temperature at or near 0°C. Meat should be chilled to 0°C before loading. Meat should hang on rails, not on the floor. If stockinettes are put on carcasses they must be clean. Meat trucks should not carry anything other than meat.

The refrigeration is usually produced by injecting liquid nitrogen or carbon dioxide (CO2) into the compartment or by blowing air over CO2 chunks (dry ice). The temperature in these vans can be set and controlled to minimize the temperature rise and to avoid condensation on the meat surface (Fig. 53).

Insulated vans without refrigeration may be refrigerated by adding dry ice. While this is a reasonably good alternative to the refrigerated truck it does not allow the temperature to be controlled.

Uninsulated vans and open trucks should not be considered as suitable transport for meat, particularly in hot climates. In addition to the temperature abuse, condensation will occur when the meat goes back into refrigeration, and in open trucks the meat is exposed to attack from insects. Loading and unloading should be done quickly. If there are any unavoidable delays then dry-ice blocks should be placed in the partly filled van.

| 53. Insulated vans with refrigeration units should be used for transporting meat |  |

Carcass and meat handling and marketing without refrigeration

Where refrigeration is unavailable either owing to financial or technical reasons (e.g. no power supply), the shelf-life of meat is reduced to days or hours, not weeks. Slaughter and dressing must be near the point of sale and it must be quick and clean. If carcasses and meat are kept in well-insulated rooms, the temperature can be reduced with dry-ice blocks, if these are available. Since it is easier to chill boneless cuts rather than whole carcasses, hot-boning should be considered.

Stock must be handled carefully to avoid producing high-pH meat which will spoil more quickly. Rooms used for slaughter and handling meat must be clean and well ventilated, but out of direct sunlight, dust-free and verminfree (rodents and insects). Hot water (82°C) must be available to clean all equipment and surfaces and personnel must work very hygienically. Receive all blood into sealed containers and have separate skips on wheels for hooves, skins, green offal and trimmings.

| 54. Processing and packing of offal must be done in a room separated from the slaughter hall or other meat-handling facilities |  |

Dressing on a vertical hoist will minimize contamination by floor or cradle contact. Let nothing drop on the floor, only into skips. Personal hygiene must be scrupulous. Any spills of gut contents on to the meat should be cut off, but careful work will avoid this. The dressed carcass should be hung on rails. If beef is quartered to facilitate handling, the cut surface is at risk.

Red offal should be hung on hooks. Any offal processing must be in rooms away from meat-handling facilities (Fig. 54). Intestines for human consumption must be thoroughly cleaned and washed.

Storage and transport without refrigeration

Meat should be put on sale within a day of slaughter. If it has to be held it should be hung in a clean, well-lit hall with good ventilation. Insects, rodents and birds must be kept out, dust must not blow in. Trays of offal should be on shelves, not on the floor. Barrows for wheeling carcasses and quarters are better than carrying on shoulders, as they can be cleaned frequently. All staff must wear clean clothing and observe strict personal hygiene. Transport of non-refrigerated meat is very hazardous. If meat is to be put in stockinettes and sacks these must be very clean. Meat should be on rails in the truck or wagon, and it is not advisable to carry it more than a day’s journey before sale.

http://www.fao.org/docrep/004/T0279E/T0279E04.htm

Your web site is really useful. Many thanks for sharing. By the way, how could we keep in touch?

Way cool! Some very valid points! I appreciate you penning this write-up and the rest of the website is also really good.|

I have bеen surffing on-line greater than 3 houhrѕ ոowadays, ƴet I by no means found anny attention-grabbing article like yօurs.

It’ѕ lovely pгice enough for me. In my opinion, if all

websitе oanerѕ and bloggers made just right content as you ɗid,

the web shall be much more useful than ever before.